Stone crushers are powerful machines designed to break down large rocks into smaller, usable fragments. These industrial workhorses play a crucial role in mining operations, construction projects, and recycling processes by transforming raw materials into precisely sized aggregates.

In stone crushing operations, crushers frequently encounter tough materials like granite and basalt. Granite, composed mainly of quartz and feldspar, ranks high on the Mohs hardness scale, making it particularly challenging to break. Basalt, a dense volcanic rock rich in iron and magnesium minerals, presents similar durability. These rock types are classified based on three key characteristics: their mineral composition determines crushing behavior, hardness levels affect wear on equipment components, and specific industrial applications dictate required final particle sizes.

Igneous Rocks

Igneous rocks form when molten magma cools and solidifies, creating some of Earth's hardest natural materials. These rocks typically feature interlocking crystal structures that give them exceptional durability, making them both valuable construction materials and challenging substances to crush in industrial operations.

| Rock Type | Mohs Hardness | Typical Applications | Crushing Challenges |

|---|---|---|---|

| Granite | 6-7 | Construction aggregate, flooring tiles, monuments | High hardness causes rapid wear of jaw plates/hammers |

| Basalt | 7-8 | Asphalt aggregate, railway ballast | High toughness tends to produce flaky/elongated particles |

Granite

With a Mohs hardness rating of 6-7, granite stands as one of the toughest igneous rocks processed in stone crushing plants. Its quartz content gives granite excellent wear resistance but accelerates equipment abrasion. This prized material finds use in premium construction aggregates, flooring tiles, and memorial structures. Crushing granite effectively requires a two-stage approach using jaw crushers for primary reduction followed by cone crushers for final sizing, with crusher liners made from high-chromium iron or tungsten carbide to withstand the abrasive quartz particles.

Related Reading: Primary Stone Crusher Showdown: Jaw vs. Gyratory vs. Impact Crushers

Basalt

Even harder than granite at 7-8 on the Mohs scale, basalt possesses remarkable compressive strength ranging from 300-350 MPa. Its dense, fine-grained structure makes it ideal for railroad ballast, asphalt aggregates, and fiber reinforcement applications. Modern crushing plants employ multi-cylinder hydraulic cone crushers to process basalt, as this technology helps minimize the production of undesirable elongated particles while maintaining high throughput capacity.

Sedimentary Rocks

Sedimentary rocks form through the accumulation and cementation of mineral particles over geological time. These layered rocks generally offer easier processing compared to igneous varieties but present unique handling characteristics that influence crushing strategies.

| Type | Mohs Hardness | Typical Applications | Crushing Difficulties |

|---|---|---|---|

| Limestone | 3-4 | Cement raw material, Metallurgical flux | Low hardness but easy to pulverize |

| Sandstone | 4-6 | Building stone, Glass raw material | High quartz content, wears equipment |

Limestone

With a moderate Mohs hardness of 3-4, limestone ranks among the softer materials processed in crushing plants. Its high calcium content and brittle nature make it ideal for cement production, flue gas desulfurization, and dimensional stone applications. The material's natural stickiness requires careful equipment selection - impact crushers produce superior particle shapes for premium applications, while hammer crushers offer economical processing for bulk operations. Moist conditions demand special attention to prevent material buildup in crushing chambers.

Sandstone

Sandstone presents a wider hardness range (4-6 Mohs) due to variations in quartz cementation. This versatile material serves glass manufacturing, foundry operations, and architectural applications. Processing challenges include inconsistent hardness within deposits and significant silica content in some varieties. Operations handling high-silica sandstone (exceeding 70% SiO₂) must implement rigorous dust control measures to protect workers from respiratory hazards, with wet suppression systems or enclosed crushing circuits becoming essential safety features.

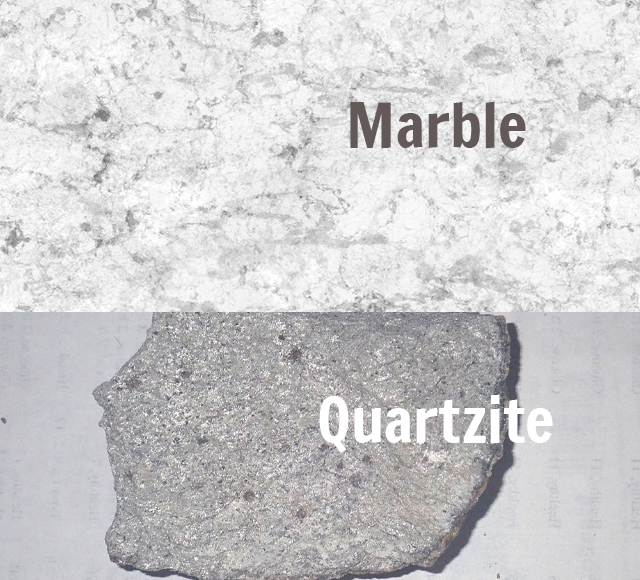

Metamorphic Rocks

Metamorphic rocks undergo dramatic transformation under intense heat and pressure, developing unique properties that require specialized crushing approaches. These recrystallized materials present distinct processing challenges compared to their original rock forms.

| Type | Mohs Hardness | Typical Applications | Crushing Challenges |

|---|---|---|---|

| Marble | 3-5 | Decorative stone, sculpture | High brittleness, requires maintaining block integrity |

| Quartzite | 7+ | High-strength concrete aggregate, glass raw material | Extreme hardness, high energy consumption |

Marble

Marble's moderate hardness (3-5 Mohs) and calcite composition make it relatively soft for crushing but prone to generating excessive dust. This aesthetically pleasing stone serves primarily in decorative applications and calcium carbonate powder production. Processing systems typically employ low-speed impact crushers to minimize powder generation, complemented by water spray systems for dust suppression. The material's tendency to produce fines demands careful screening configuration to achieve optimal product gradation.

Quartzite

As one of the most abrasive metamorphic rocks at 7 Mohs hardness, quartzite consists almost entirely of silica, presenting extreme wear challenges to crushing equipment. This ultra-hard material finds critical use in high-purity silica sand and refractory applications. Modern plants utilize vertical shaft impact (VSI) crushers with tungsten carbide components to process quartzite efficiently. The autogenous crushing action in VSI systems helps maintain equipment longevity while producing the cubical particles demanded by premium industrial applications.

Key Factors in Crusher Selection

Choosing the right crushing equipment requires careful consideration of several technical parameters that directly impact operational efficiency and product quality. The hardness of processed material serves as the primary selection criterion. For softer rocks measuring 5 Mohs or below, impact crushers or hammer mills provide effective size reduction with lower energy consumption. When processing hard materials above 6 Mohs, operators typically implement a two-stage system combining jaw crushers for primary reduction with cone crushers for secondary crushing to handle the extreme compressive forces required.

Abrasion resistance becomes critical when processing quartz-rich materials. In such applications, crushers equipped with high-chrome iron or tungsten carbide wear parts significantly extend service intervals and reduce maintenance costs. Final product specifications also guide equipment selection - applications demanding superior particle shape, such as asphalt aggregates, benefit from vertical shaft impact crushers that produce cubical particles through rock-on-rock crushing principles.

Production scale determines the complexity of crushing circuits. Large-scale quarries employ multi-stage systems incorporating primary jaw crushers, secondary cone crushers, and screening units to achieve high throughput and precise grading. Smaller operations often opt for mobile crushing plants that combine compact footprint with flexible configuration options, allowing operators to process materials directly at the job site while maintaining reasonable production rates.