What is Crushed Stone?

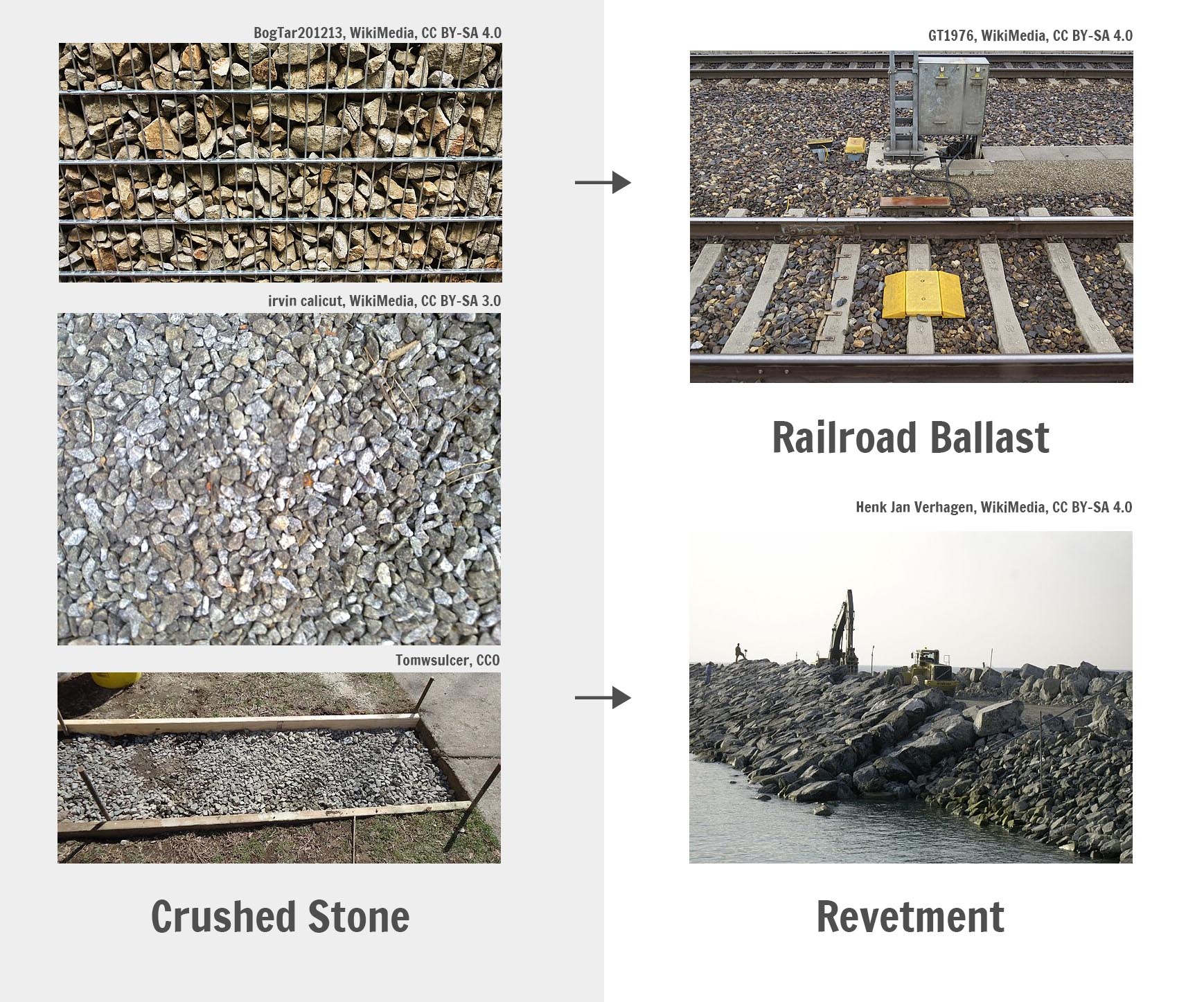

Crushed stone refers to angular rock fragments ranging from 5-150mm in size, produced through mechanical crushing processes. Unlike naturally rounded gravel formed by water erosion, crushed stone maintains sharp edges due to intentional fracturing in industrial crushers, resulting in better interlocking properties for construction applications.

Granite provides exceptional durability for heavy-duty applications, while limestone offers cost-effective solutions for road bases. Basalt delivers superior strength in concrete mixtures. Recycled concrete aggregates demonstrate environmental benefits by repurposing demolition waste into new construction materials, reducing landfill dependency.

Core Uses of Crushed Stone

Railroad Ballast: The Foundation of Train Tracks

Crushed stone serves as railroad ballast, providing essential drainage and stability for train tracks. The angular shape of the stones creates interlocking effects that help maintain track alignment under heavy loads and vibrations.

Revetment Stone: Protecting Against Water Erosion

In flood control projects, crushed stone acts as revetment stone to prevent shoreline erosion. Engineers carefully select stone sizes and gradations to withstand the force of flowing water while maintaining structural integrity.

Building the Modern World

Crushed stone forms the backbone of construction materials, serving as concrete aggregate that binds with cement to create durable structures. It also provides a stable base layer for asphalt roads, ensuring even weight distribution and longevity of paved surfaces.

The Crushed Stone Crushing Process

Primary Crushing: Breaking Down the Big Rocks

The journey begins with massive raw stones being fed into a jaw crusher. This rugged machine uses powerful compressive forces between two metal plates to reduce boulders into manageable 150-300mm fragments, much like a giant mechanical nutcracker breaking granite or basalt into smaller pieces.

Secondary Crushing and Precise Sizing

After primary crushing, cone crusher or impact crusher take over to further refine the material. Cone crushers gently compress stones between rotating mantles, while impact crushers use high-speed rotors to fracture rocks through kinetic energy. The crushed material then passes through vibrating screens that precisely separate particles into standard sizes like #57 (9.5-25mm) or #3 (50-75mm) aggregates.

Final Cleaning and Quality Assurance

The crushed stone undergoes thorough washing to remove clay and organic impurities, ensuring compliance with strict international standards such as ASTM C33 or EN 12620. Advanced testing methods verify the material's strength, shape characteristics, and durability before it's approved for construction applications.

Key Differences Between Crushed Stone and Natural Gravel

Crushed stone and natural gravel serve distinct purposes in construction due to their fundamental physical characteristics. The angular edges of crushed stone particles create superior interlocking capabilities, making them ideal for load-bearing applications where shear strength is critical. In contrast, the naturally rounded surfaces of gravel particles allow for better water permeability and aesthetic appeal in landscaping projects.

Physical Property Comparison

The angularity of crushed stone results from mechanical fracturing during the crushing process, creating rough surfaces that enhance frictional resistance. This geometric property directly translates to improved stability in structural applications. Natural gravel, formed through prolonged water erosion, develops smooth rounded shapes that reduce internal friction but facilitate better drainage characteristics.

Application Selection Guide

Engineers typically specify crushed stone for road base construction and concrete aggregate where particle interlock prevents displacement under heavy loads. Gravel finds optimal use in French drain systems, decorative landscaping, and other scenarios where water flow or visual appearance takes precedence over structural requirements.

Sustainability and Future Trends

The Rise of Recycled Crushed Stone

Modern stone crushers now play a crucial role in sustainable construction by processing demolished concrete and building debris into high-quality recycled aggregates. These machines transform construction waste into reusable materials for roads, foundations, and new buildings, significantly reducing landfill needs and preserving natural stone resources.

Low-Carbon Production Innovations

The industry is shifting toward environmentally friendly solutions like electric-powered crushers that eliminate diesel emissions. Advanced dust suppression systems now capture over 95% of particulate matter during operation, while smart energy recovery systems convert vibration energy into reusable electricity, making crushing operations cleaner than ever before.