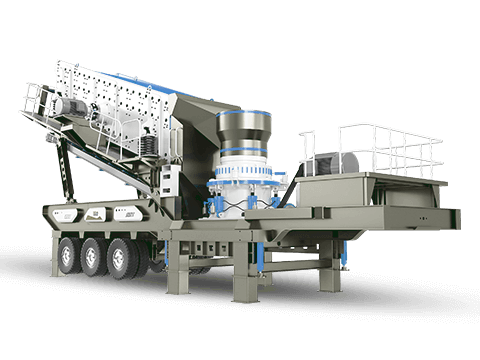

Mobile crushing plants offer unparalleled advantages in modern material processing operations, with mobility and rapid deployment standing as their most compelling benefits. Unlike traditional stationary plants requiring three months for installation, mobile units can be operational within 24 hours - as demonstrated in an iron ore project where production commenced immediately after machine positioning. This remarkable flexibility enables temporary mining sites to maximize productivity during limited operational windows.

The economic benefits of mobile crushers extend beyond fast setup times. Operators save approximately 30% in initial capital expenditure by eliminating the need for permanent concrete foundations and extensive site preparation. The innovative diesel/electric dual-power design provides additional cost efficiencies, particularly in remote locations where electrical infrastructure may be unreliable or unavailable, allowing operations to switch between power sources based on availability and cost considerations.

These combined advantages make mobile crushing plants the superior choice for projects requiring quick startup, temporary operations, or frequent relocation. The technology effectively bridges the gap between production requirements and infrastructure limitations, delivering professional-grade crushing performance wherever needed, whenever needed.

Application Scenario

C&D Waste Recycling

Construction and demolition (C&D) waste recycling presents unique material challenges, primarily consisting of concrete fragments, brick rubble, and reclaimed asphalt pavement. These materials demand specialized processing solutions to transform demolition debris into valuable recycled aggregates for new construction applications.

Optimal equipment configurations typically combine jaw and impact crushers in sequence - exemplified by setups jaw crusher paired with the impactor. This tandem approach efficiently reduces mixed debris while producing cubical end products. Advanced systems integrate magnetic separators directly onto discharge conveyors, enabling automatic ferrous metal recovery during the crushing process without additional handling steps.

The environmental and economic benefits are demonstrated in real-world applications like a Chinese urban redevelopment project, where a mobile crushing line achieved remarkable 90% material recovery rates. Such systems allow on-site processing of demolition waste, converting what was once disposal cost into saleable recycled aggregates while dramatically reducing transportation needs and landfill dependence.

→ C&D Waste Recycling Solution

Mining & Quarrying

Short-term pit operations demand specialized crushing solutions, particularly when dealing with scattered mineral deposits and unpredictable ore grades - common scenarios in African gold exploration projects. Mobile crushing units provide distinct advantages in these conditions by relocating in sync with advancing mine faces, dramatically reducing haulage distances and associated fuel costs while improving overall operational efficiency.

Hard rock crushing presents significant technical challenges that require robust engineering solutions. Modern mobile cone crushers like the Metso Lokotrack LT300HP address these demands through advanced hydraulic adjustment systems. These systems enable real-time calibration of crushing parameters to maintain optimal performance when processing tough materials, while offering quick setup times and relocation flexibility essential for exploratory mining operations.

The combination of mobility and high-performance crushing technology creates new possibilities for mineral extraction in challenging environments. Operators can now establish temporary processing hubs near active mining faces, adjusting equipment configurations as ore characteristics change, while maintaining consistent output quality despite varying feed material conditions.

→ Mining and Quarrying Solution

Road Construction

In-situ crushing revolutionizes road rehabilitation by processing existing pavement materials directly at the construction site. This approach transforms worn asphalt surfaces into high-quality Recycled Asphalt Pavement (RAP) aggregate, eliminating waste while preserving valuable binder content. European case studies demonstrate the environmental benefits, with mobile crushing setups reducing material transport-related carbon emissions by 45% compared to conventional methods requiring off-site processing.

Mountainous terrain and confined worksites demand specialized equipment configurations. Compact crushers combine full-scale crushing performance with space-efficient designs, enabling operation along winding mountain roads where conventional plants cannot deploy. Their optimized footprints maintain safety margins while processing materials in challenging topography.

Modern mobile crushers incorporate features specifically beneficial for road construction applications. Automatic gap adjustment maintains consistent RAP gradation despite varying feed materials, while integrated dust suppression systems address environmental concerns in populated areas. These technological advancements allow contractors to rehabilitate road networks with greater efficiency and sustainability than traditional methods.

Agricultural & Biomass

Agricultural biomass processing requires specialized crushing solutions tailored to organic materials. Lightweight rotor crushers have been specifically engineered to handle delicate fibrous materials like corn stalks, precisely reducing them to ≤50mm particles ideal for biogas feedstock. These machines maintain material integrity while achieving the necessary particle size distribution for optimal anaerobic digestion performance.

Safety takes priority when processing dry agricultural materials, with advanced crushers incorporating ATEX-certified explosion-proof designs. These systems feature comprehensive dust containment measures including sealed bearings, spark-resistant components, and integrated suppression systems that mitigate the risk of combustible dust ignition - a critical consideration when handling grain byproducts and other organic particulates.

The latest biomass crushers combine gentle material handling with high throughput capacity, featuring adjustable speed rotors that prevent fiber wrapping while maintaining energy efficiency. Specialized wear materials resist the corrosive effects of moist organic matter, ensuring reliable operation in demanding farm and biorefinery environments where conventional crushers would quickly degrade.

→ Aggregate Processing Solution

Limitations and Inapplicable Scenarios

Material characteristics significantly influence crusher selection, with certain properties posing operational challenges. Highly viscous materials like lateritic nickel ore frequently cause feed hopper clogging due to their adhesive nature, requiring specialized vibratory feeders or pre-screening systems. For extremely hard minerals measuring Mohs 7 and above, conventional crushing methods become inefficient - these applications typically benefit from stationary high-pressure grinding rolls (HPGRs) that apply sustained compressive forces rather than impact fragmentation.

Project duration emerges as another critical selection factor. While mobile crushers offer advantages for short-to-medium term operations, fixed plants demonstrate superior cost efficiency in long-duration projects exceeding two years of continuous operation. The permanent installations allow for optimized maintenance schedules, easier access to major components, and reduced wear part replacement frequency - factors that collectively lower total operating costs over extended production periods.

Environmental conditions also dictate equipment suitability. Sites with extreme temperature variations or corrosive atmospheres often require stationary plants with enhanced protection systems, as mobile units may lack the necessary environmental hardening for reliable long-term performance in such demanding conditions.

Key Selection Parameters

| Factor | Mobile Solution | Stationary Solution |

|---|---|---|

| Project Duration | <2 years | >5 years |

| Site Relocation Frequency | Monthly moves | Fixed location |

| Maximum Feed Size | ≤800mm (limited by onboard hopper) | ≤1500mm (customizable feed bins) |

| Environmental Compliance | Requires additional exhaust treatment (Tier 4F) | Easier centralized dust collection |

Mobile units sacrifice some feed capacity and require more frequent environmental retrofitting, but gain crucial mobility advantages for short-term projects. Stationary plants achieve greater processing capacity and simpler compliance management, making them better suited for permanent installations where relocation isn't required.