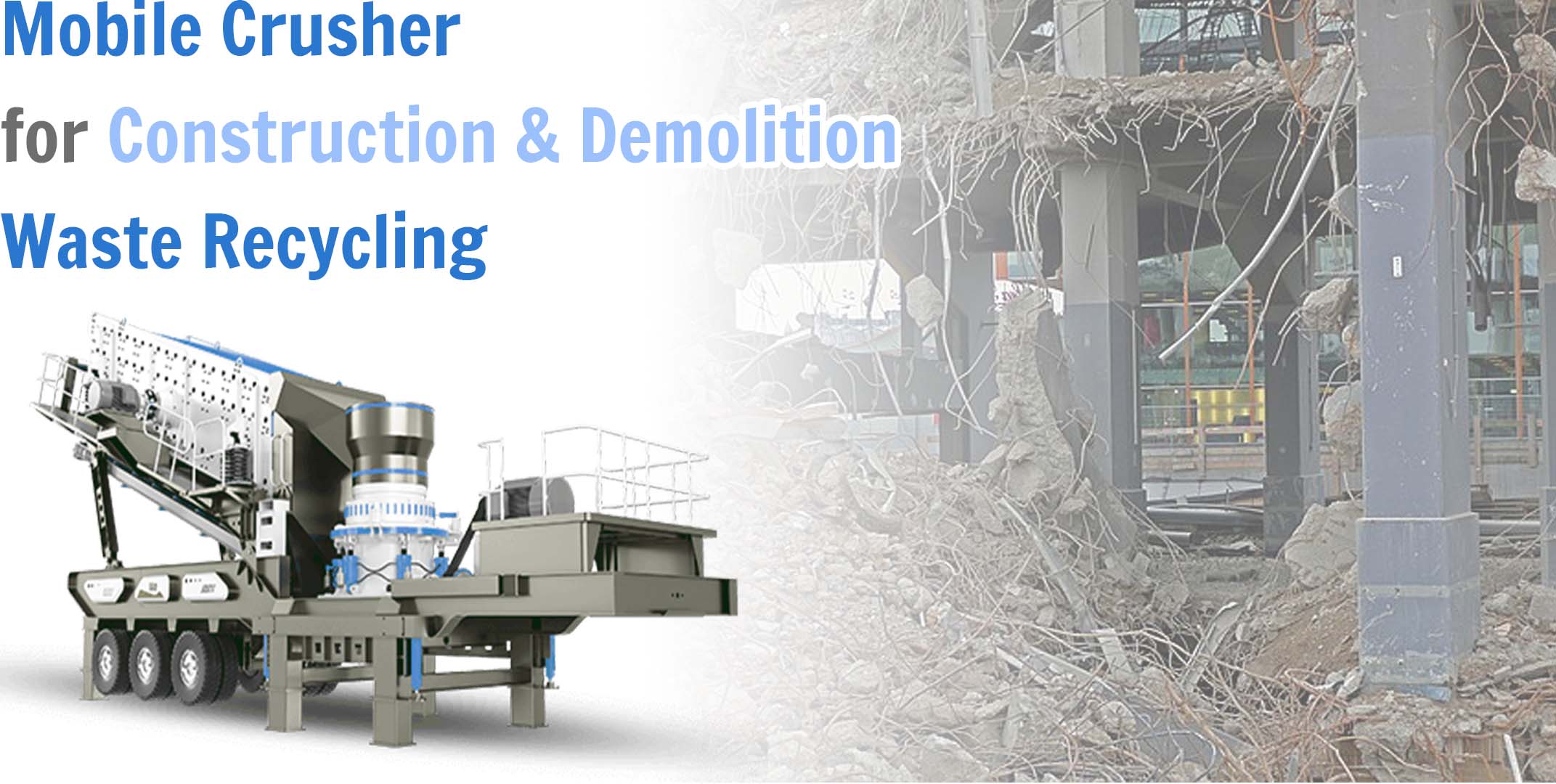

Mobile crusher revolutionize material processing by eliminating the constraints of fixed installations. Their self-contained design combines crushing power with unprecedented mobility, allowing operations to move directly to material sources rather than transporting raw feed to stationary plants. This capability proves particularly valuable in modern construction projects where time efficiency and site flexibility are paramount.

The engineering behind mobile units focuses on maintaining robust crushing performance while achieving compact transport dimensions. Advanced hydraulic systems enable rapid setup times, often requiring less than 30 minutes for full operational readiness. This operational agility transforms project planning, as contractors can schedule crushing activities precisely when and where needed throughout dynamic construction timelines.

Tracked and wheeled chassis systems give mobile crushers exceptional site adaptability for urban demolition projects. Unlike traditional stationary plants that require permanent foundations, these mobile units can operate on temporary sites without extensive preparation. Their ability to navigate rough terrain and confined urban spaces makes them ideal for processing construction debris directly at demolition locations.

The environmental benefits of on-site waste processing are significant. By crushing and recycling materials where they're generated, mobile crushers dramatically reduce truck traffic and associated emissions. Modern units incorporate dust suppression systems and noise reduction technologies, making them suitable for sensitive urban environments while maintaining high throughput capacities.

Modular configurations allow mobile crushers to transform according to specific material processing requirements. Operators can select between jaw crushers for hard, dense materials like reinforced concrete, or impact crushers for softer demolition waste containing bricks and mortar. This customization extends beyond the primary crushing stage to include various screening options for precise product classification.

The integrated vibrating screen modules create closed-loop processing systems that deliver finished products in a single pass. Advanced control systems automatically adjust crusher parameters based on feed material characteristics, optimizing performance while protecting the equipment. This intelligent design approach enables contractors to handle diverse material streams with a single versatile machine.

Key Technological Configurations for Construction Waste Processing

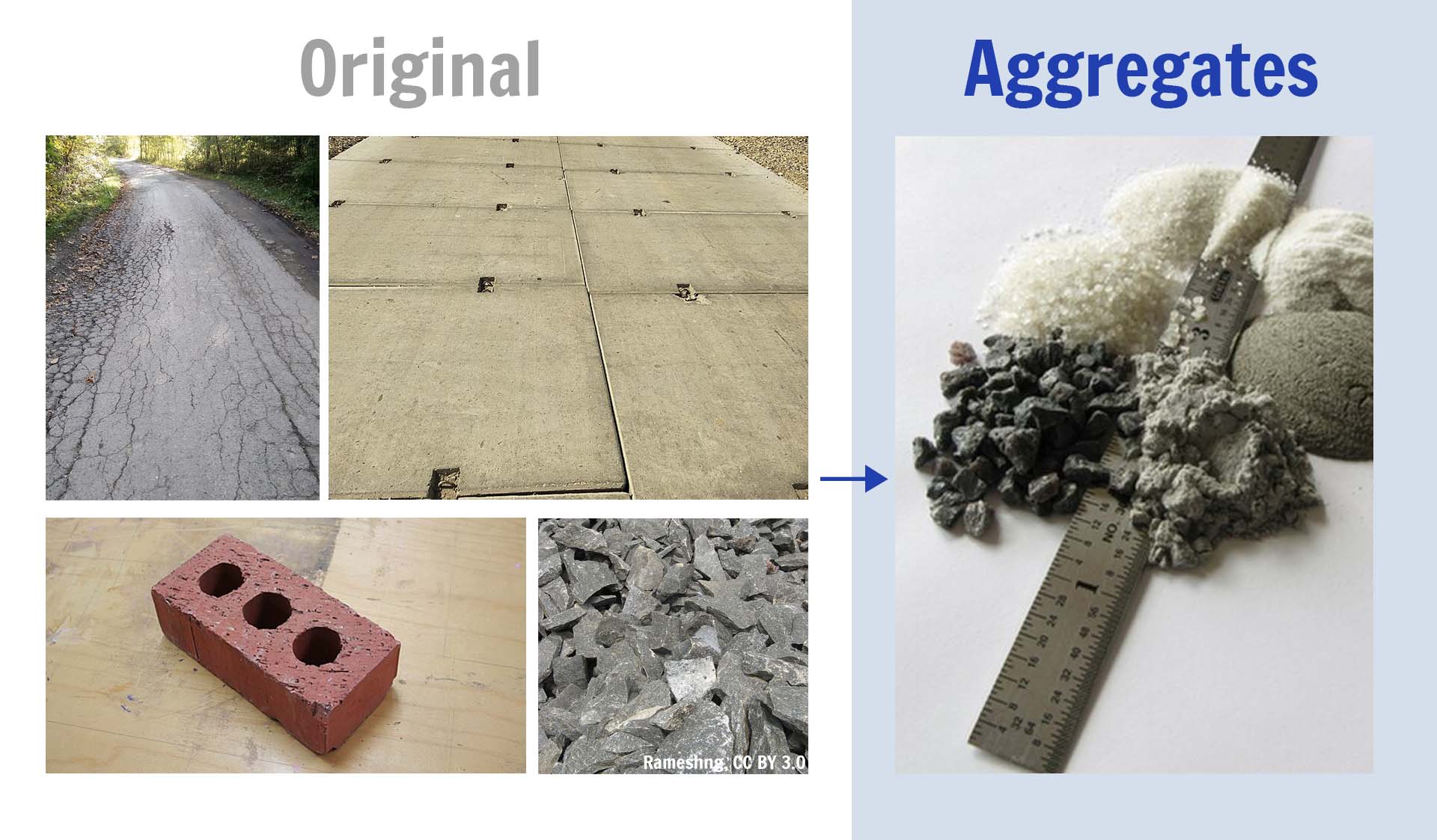

The effective handling of construction waste relies on specialized crushing equipment configurations. Jaw crusher serve as the primary workhorse for processing high-strength concrete debris, utilizing compressive force between fixed and movable plates to reduce bulk materials into manageable fragments. Their robust construction and adjustable discharge settings make them ideal for initial size reduction of demolition concrete with embedded rebar or aggregate.

For processing mixed masonry waste like bricks and tiles, impact crushers demonstrate superior efficiency through kinetic energy fragmentation. The high-speed rotor and impact plates create multiple fracture points within brittle materials, producing more uniform particle shapes compared to compression-based methods. This characteristic proves particularly valuable when processing recycled aggregates for new concrete production where cubical particle geometry enhances binding properties.

Screening and Conveying System Optimization

Advanced screening systems incorporate electromagnetic separators and air classifiers to remove metal contaminants from crushed construction waste. Multi-deck vibrating screens with progressively finer mesh sizes enable precise grading of recycled aggregates while simultaneously extracting ferrous materials through overhead magnetic crossbelt separators. This integrated purification process ensures the final product meets structural material specifications without compromising processing throughput.

Radial telescopic conveyors address spatial constraints typical at urban demolition sites by offering adjustable discharge ranges up to 90 degrees. Their collapsible frame design allows compact transportation between job sites while maintaining continuous material flow during operation. This mobility feature proves critical when processing temporary stockpiles in congested environments where conventional fixed conveyors would require frequent repositioning.

Environmental and Economic Benefits Analysis

Carbon Emission Reduction

Stone crushers significantly reduce carbon footprints by enabling on-site material processing. When construction waste or natural rocks are crushed directly at demolition sites or quarries, it eliminates the need for multiple truck trips to transport raw materials to distant processing plants. A single mobile crusher unit operating on-site can prevent hundreds of tons of CO2 emissions annually that would otherwise be generated by diesel-powered haulage vehicles.

The environmental advantage extends further when crushed recycled aggregates replace virgin materials. Using demolition concrete as aggregate reduces mining activities for natural gravel by approximately 30-40% per project. This substitution not only preserves natural landscapes but also lowers the energy-intensive extraction and processing emissions associated with virgin aggregate production, creating a double carbon saving effect.

ROI Analysis

From an economic perspective, stone crushing systems demonstrate compelling return-on-investment when compared to traditional waste disposal methods. While landfill costs continue rising globally - averaging $50-150 per ton in developed nations - crushed recycled materials generate $15-80/ton in revenue depending on aggregate quality and local market demand. A medium-sized recycling operation can convert 90% of incoming construction waste into sellable products, transforming disposal expenses into profit streams.

Government incentives further enhance financial viability. Many regions offer tax credits or grants for equipment purchases that support circular economy practices. Green building certification programs like LEED award additional points for using recycled aggregates, creating premium pricing opportunities for contractors. These policy measures typically recover 20-40% of crusher equipment costs over five years, accelerating payback periods while supporting sustainability goals.

Typical Applications and Industry Trends

Typical Applications

Stone crushers play a vital role in construction and demolition waste (C&D) sites, where they transform bulky concrete slabs, bricks, and asphalt into reusable aggregates. These processed materials can be directly utilized in new construction projects, reducing landfill burdens and conserving natural resources. The machines' adjustable crushing chambers allow operators to produce specific grain sizes required for road bases, drainage layers, or structural backfill applications.

During disaster recovery operations, mobile stone crushers provide rapid on-site processing of collapsed building debris. Their ability to crush mixed materials (reinforced concrete, masonry, and metal fragments) without pre-sorting significantly accelerates cleanup timelines. This immediate rubble processing prevents secondary transportation costs and enables faster reconstruction by supplying processed materials directly at the disaster site.

Future Development Directions

The industry is witnessing a decisive shift toward electric-powered crushers, particularly for urban construction projects with strict emission regulations. These zero-emission units combine high-torque electric motors with advanced battery systems, delivering comparable performance to diesel models while eliminating exhaust fumes and noise pollution. Solar-assisted charging stations are being tested to further enhance the sustainability of these electric crushing systems.

Remote monitoring technologies represent another transformative trend, with crushers now equipped with IoT sensors that track wear patterns, vibration levels, and production metrics in real-time. This data enables predictive maintenance, automatically scheduling part replacements before failures occur. Some advanced systems even utilize machine learning to optimize crushing parameters based on material hardness variations, reducing energy consumption by up to 20% while maintaining consistent output quality.