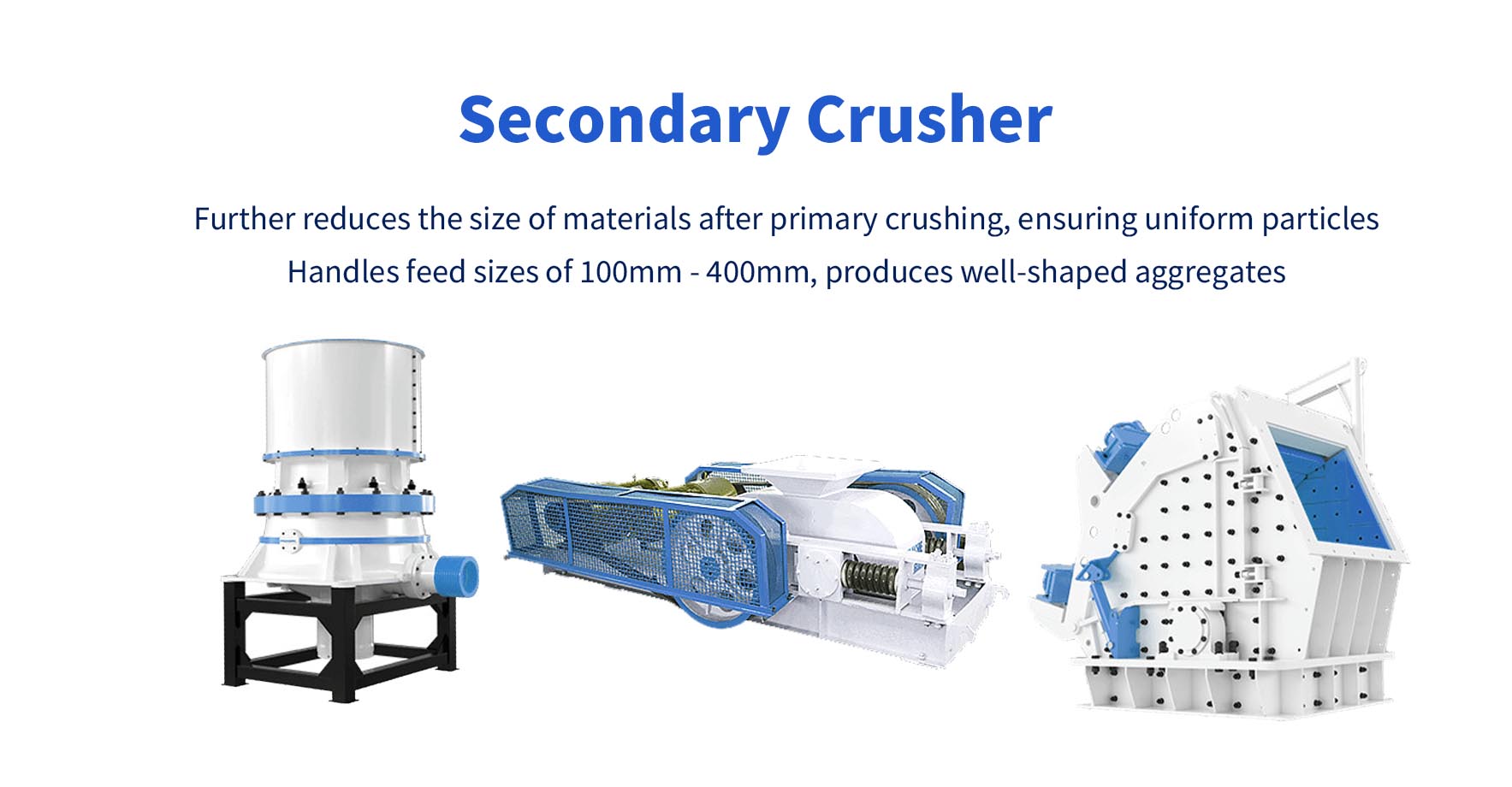

Secondary crusher serve as the vital transition stage between primary crushing and tertiary crushing in industrial mineral processing. They receive coarse materials ranging from 200-400mm in size from primary jaw crusher or gyratory crusher, and systematically reduce them to intermediate-sized particles of 40-100mm. This precise size reduction bridges the gap between initial rock fragmentation and final product refinement, creating optimal feed conditions for subsequent processing stages or direct engineering applications.

The strategic positioning of secondary crushers in the production line ensures continuous material flow while preventing downstream equipment overload. These machines process partially crushed but still irregular materials from primary crushing, transforming them into more manageable intermediate products. Modern secondary crushing technology focuses on maintaining consistent throughput while achieving particle size targets, which is essential for efficient operation of the entire crushing circuit.

A key performance indicator for secondary crushers is their ability to produce cubical particles with minimal flaky or elongated content. Unlike primary crushers that prioritize size reduction capacity, secondary units emphasize particle shape optimization through controlled compression or impact crushing mechanisms. The geometry of crushing chambers and the kinematics of moving components are carefully engineered to promote inter-particle crushing, which naturally improves particle shape characteristics.

The quality of output from secondary crushers directly determines the efficiency of subsequent processing stages or the performance characteristics of final products. When producing aggregates for road bases or concrete applications, the secondary crushing stage must deliver materials with proper gradation and physical properties. Advanced secondary crushers incorporate automatic adjustment systems that maintain consistent product size distribution even as wear parts gradually deteriorate during operation.

Comparison of Three Main Secondary Crusher Technologies

Cone Crusher

Cone crushers are specifically designed for processing high-hardness rocks such as granite and basalt. These machines utilize a unique compression crushing mechanism where the material is squeezed between a mantle and concave liner. The hydraulic system not only provides consistent crushing force but also features automatic tramp iron protection, which safeguards the equipment from damage caused by uncrushable materials.

The crushing chamber geometry in cone crushers creates a progressive compression zone, allowing for efficient size reduction of hard materials. Modern cone crushers incorporate advanced automation systems that continuously monitor and adjust the crushing parameters, ensuring optimal performance and product shape. The closed-side setting can be precisely controlled to produce uniform particle sizes suitable for demanding applications like high-grade concrete aggregates.

Impact Crusher

Impact crusher excel in processing medium-hard materials like limestone and recycled concrete where particle shape is critical. The machine operates by accelerating the feed material into stationary impact plates using a high-speed rotor. The adjustable rotor speed allows operators to optimize the balance between impact crushing and grinding effects, known as the S/F (Striking/Friction) ratio, to achieve the desired product characteristics.

This technology is particularly valuable for producing high-quality manufactured sand where cubical particles are required. Impact crushers can handle materials with higher moisture content compared to other crushers, and their ability to process contaminated materials makes them ideal for recycling applications. The impact crushing action naturally creates better particle shape with fewer elongated or flaky particles, reducing the need for additional shaping processes.

Roll Crusher

Roll crusher specialize in processing medium-hard brittle materials such as coal and salt for intermediate and fine crushing applications. These machines feature two counter-rotating rolls that compress and fracture the material as it passes through the narrowing gap between them. Operators can choose between toothed rolls for better grip on materials or smooth rolls for producing finer, more uniform products.

The relatively low-speed operation of roll crushers makes them energy-efficient while generating minimal fines, which is crucial for applications like coal preparation where excessive dust creation is undesirable. The adjustable gap between rolls allows for precise control over product size. Their compact design and ability to handle materials with high moisture content make roll crushers particularly suitable for processing soft to medium-hard minerals in confined spaces.

Process Optimization Points for Secondary Crushing

Secondary crushing plays a crucial role in achieving the desired final product specifications. The process focuses on further reducing material size after primary crushing while maintaining efficiency and minimizing energy consumption. Proper optimization ensures consistent output quality and extends equipment service life.

Synchronization with Primary Crushing

The coordination between jaw crusher discharge settings and cone crusher feed size represents a critical factor in secondary crushing efficiency. Maintaining an ideal ratio of 1:1.5 between the jaw crusher's discharge opening and the cone crusher's feed size creates optimal material flow. This proportion allows for smooth transition of material while preventing choking or excessive wear in the secondary crusher.

Surge bins serve as essential components in bridging primary and secondary crushing stages. These intermediate storage units absorb fluctuations in material flow from the primary crusher, preventing direct impact feeding that could damage the secondary crusher components. Properly designed surge bins maintain consistent feed rates and protect downstream equipment from sudden material surges.

Particle Size Control Techniques

Modern cone crushers utilize hydraulic systems for real-time adjustment of the closed side setting (CSS), enabling precise control over final product size. This dynamic adjustment capability allows operators to respond immediately to changes in feed material characteristics or production requirements. The hydraulic system provides both operational flexibility and protection against uncrushable materials entering the crushing chamber.

Pre-screening technology significantly improves secondary crushing efficiency by separating fines before they enter the crusher. This process reduces recirculation of already properly sized material, minimizing energy waste and decreasing wear on crushing components. Effective pre-screening leads to higher throughput rates and more uniform final product gradation while preventing the over-crushing phenomenon.

Industry Application Scenarios: An In-Depth Analysis

Case Study: Aggregate Production Line

In granite crushing operations, the wear resistance of cone crusher components plays a crucial role in operational efficiency. The Mn18Cr2 liner plates demonstrate exceptional durability under continuous compressive stress, typically achieving 3,000-5,000 operational hours before replacement. This manganese steel alloy maintains structural integrity while subjected to repeated impact forces exceeding 200 MPa, making it ideal for processing abrasive igneous rock formations. The liner's service life directly impacts production costs, with proper maintenance reducing downtime by up to 40% compared to standard carbon steel alternatives.

Modern aggregate plants implement predictive maintenance systems using ultrasonic thickness measurement to monitor liner wear patterns. These systems analyze crushing chamber geometry changes caused by progressive material abrasion, allowing operators to schedule replacements during planned maintenance windows. The optimized crushing chamber profile maintained by Mn18Cr2 liners ensures consistent particle size distribution between 20-50mm for downstream concrete batching processes.

Recycled Aggregate Production

Impact crushers demonstrate remarkable efficiency in construction waste processing through their built-in material separation capabilities. The rotor assembly's kinetic energy, often exceeding 80 m/s tip speed, effectively fractures concrete debris while liberating embedded reinforcement bars through inertial separation. This process achieves over 90% metal recovery rates without additional magnetic separation equipment, making it particularly suitable for urban demolition waste recycling.

The crusher's adjustable grinding path and impact plate gap (typically 30-100mm) allow operators to balance production throughput with final product quality. Secondary impact zones within the crushing chamber further refine particle shape, producing cubical aggregates that meet ASTM C33 specifications for recycled concrete applications. Modern units incorporate intelligent overload protection that automatically detects non-crushable objects like steel beams, preventing catastrophic mechanical failures.

Special Mineral Processing

Roll crushers have become indispensable in potash mineral processing due to their precise particle size control in closed-circuit systems. The counter-rotating rolls, operating at differential speeds of 1:1.25 to 1:1.5, generate both compressive and shearing forces ideal for friable evaporite minerals. This configuration produces minimal fines below 2mm while maintaining product uniformity crucial for subsequent flotation processes in fertilizer production.

Advanced systems integrate real-time particle size analyzers that automatically adjust roll gap settings between 10-50mm based on feed composition variations. The closed-loop crushing circuit, typically coupled with high-frequency screens, achieves 95% process efficiency with energy consumption below 2.5 kWh/ton. Dust suppression systems using compressed air curtains maintain workplace safety by reducing airborne particulates beneath OSHA permissible exposure limits.

Maintenance and Innovation Trends

Key Component Maintenance Guide

The spherical roller bearing in cone crusher main shafts requires precise lubrication intervals to prevent premature wear. Industry standards typically recommend greasing every 500 operating hours or monthly, whichever comes first, using high-temperature lithium complex grease. Advanced lubrication systems now incorporate automated dispensers with pressure sensors to maintain optimal film thickness during crushing operations.

For monitoring blow bar wear in impact crushers, AI vision systems have revolutionized maintenance practices. These systems use high-resolution cameras to capture real-time images of the crushing chamber, with machine learning algorithms analyzing wear patterns. When the system detects critical wear thresholds (usually at 30% remaining thickness), it automatically alerts operators for replacement scheduling, significantly reducing unplanned downtime.

Technological Evolution Directions

Smart crushing technology represents a major leap forward in operational efficiency. Modern systems equipped with hardness sensors can automatically adjust crusher parameters like RPM and CSS based on real-time material analysis. For granite processing, the system might increase crushing force while reducing speed, whereas for softer limestone it optimizes for throughput, all without operator intervention.

The development of hybrid power secondary crushers combines electric motors with energy recovery systems. During normal operation, the electric motor provides consistent power, while a capacitor bank stores energy from the crusher's rebound motion. Field tests show energy savings of 15-22% compared to conventional models, making them particularly effective in large-scale aggregate production where secondary crushing accounts for significant power consumption.