Core Differences in Crushing Principles

The fundamental distinction between an Impact Crusher and a Hammer Crusher lies in their force application methods. Impact crushers utilize kinetic energy from high-speed rotors to propel materials against stationary impact plates, creating a shattering effect through abrupt deceleration. In contrast, hammer crushers employ direct percussion through rotating hammer heads that strike materials against grate bars, achieving size reduction through repetitive blunt force impacts.

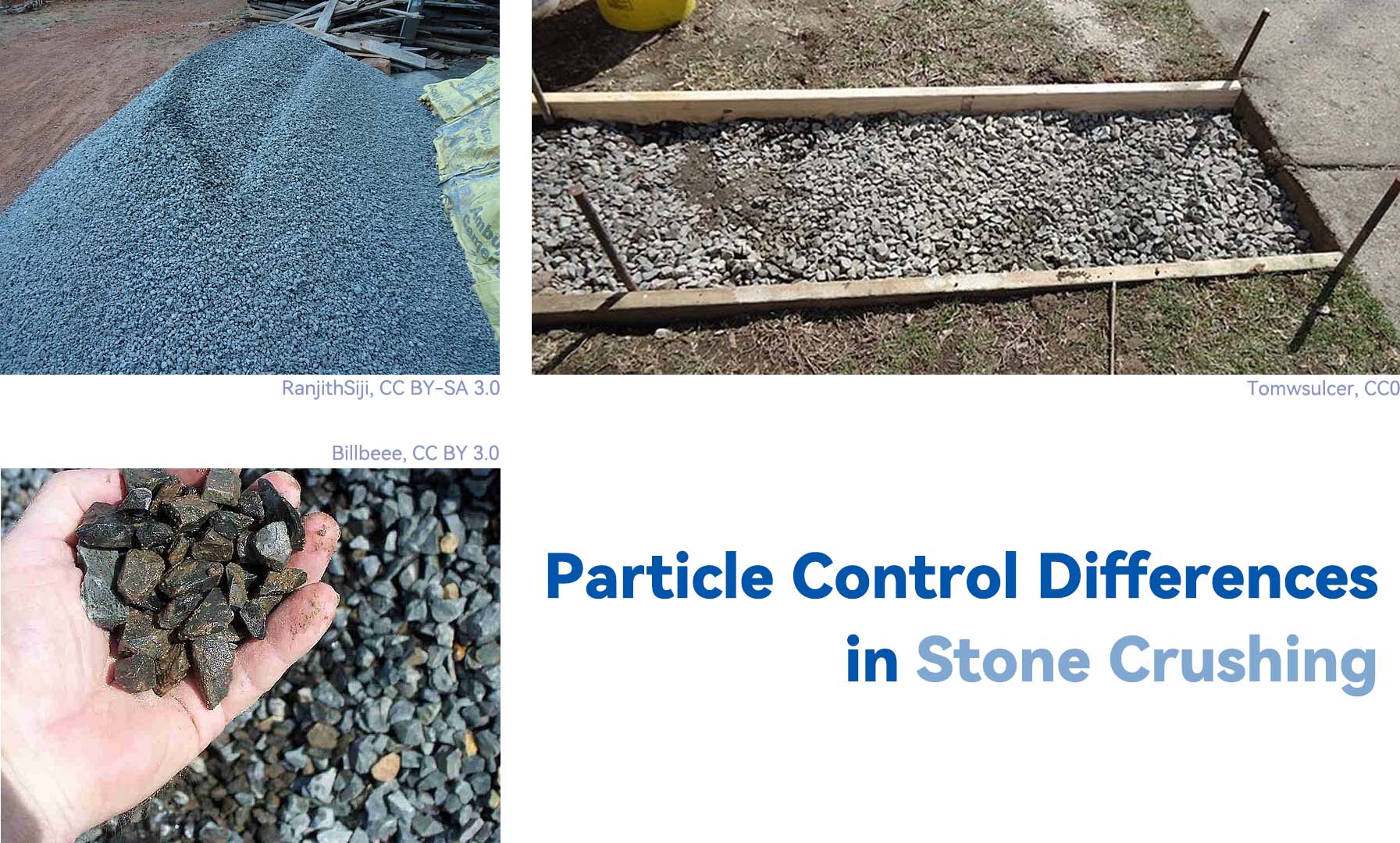

The dynamics of impact crushing versus hammer crushing reveal distinct material behavior patterns. Impact crushing facilitates particle disintegration through sudden stress waves propagation, often producing more cubic-shaped aggregates. Hammer crushing relies on progressive fracturing through multiple strikes, typically yielding more irregular particle geometries. These differences significantly influence downstream processing efficiency and product quality in applications ranging from aggregate production to mineral processing.

Impact Crusher's Impact-Rebound Fragmentation Mechanism

The Impact Crusher operates on a sophisticated impact-rebound principle where materials first collide with high-speed rotor-mounted blow bars before being propelled against impact plates. This primary impact initiates microfractures within the material structure, while subsequent collisions between particles (secondary impact crushing) further refine the particle size distribution. The continuous impact events create controlled fragmentation patterns that enhance particle shape characteristics.

Modern impact crushers employ closed-circuit systems to optimize particle shaping. By recirculating oversized materials through the crushing chamber, these machines achieve superior cubicity while maintaining precise control over discharge sizing. This mechanism proves particularly effective in applications requiring well-graded aggregates for construction or high-quality mineral concentrates.

Hammer Crusher's Chamber Dynamics

Hammer Crushers demonstrate unique crushing chamber dynamics through their combined impact and screening functions. The rotating hammer assembly generates powerful direct strikes while the strategically positioned grate bars provide simultaneous size classification. This dual-action mechanism creates a constrained crushing environment where materials undergo forced fragmentation until reaching the required discharge dimensions.

The linear velocity of hammer heads critically determines particle breakage patterns in hammer crushers. Higher rotational speeds produce greater impact energy but may increase fines generation, while lower velocities favor coarser outputs. Proper adjustment of hammer speed and grate spacing allows operators to balance production capacity with product size distribution, making these crushers versatile for various mineral processing and recycling applications.

Shape Control Comparison of Finished Particles

The geometric characteristics of crushed aggregates vary significantly between different crushing systems, primarily due to their distinct working principles. Impact crushers and hammer crushers, two common secondary crushing machines, demonstrate notable differences in producing angular versus more rounded particles. These shape variations directly influence the material's bulk density, workability in concrete mixes, and interlocking properties in road bases.

Industry studies reveal that impact crushers typically yield aggregates with over 85% cubical content, while hammer crushers often produce 15-30% flaky particles depending on feed material. The adjustable gap between impact plates and grate bars serves as a critical parameter for shape optimization. Through precise adjustments, operators can enhance particle rounding or maintain desirable angularity for specific applications like asphalt production or high-strength concrete.

Impact Crusher's Cubical Particle Advantage

Impact crushers achieve superior cubicity through multi-directional impact forces generated by high-speed rotors striking materials against adjustable impact plates. This mechanism creates multiple fracture planes within each particle, forming geometrically stable cubic shapes. Modern designs like adjustable impact plates allow real-time modification of crushing angles, producing optimized particle shapes for premium concrete aggregates.

The cubical content in impact crusher output frequently exceeds 85%, with less than 5% flakiness index in well-configured systems. This performance makes them ideal for producing high-value construction materials where particle shape directly affects product performance. The EU-type impact crushers particularly excel in shape control through their segmented impact plate design.

Hammer Crusher's Shape Limitations

Hammer crushers predominantly apply unidirectional impact through rotating hammers, often resulting in elongated or flat particles due to preferential fracture along material weaknesses. While the grate bar assembly provides some particle rounding effect on finer fractions, coarser output still contains significant flaky content. Material properties substantially influence these outcomes—brittle rocks tend to shatter into more angular fragments, while laminated materials produce higher flakiness.

The sensitivity to feed characteristics presents challenges in maintaining consistent particle shapes, especially when processing mixed demolition waste or heterogeneous geological deposits. Although PCZ heavy hammer crushers improve shape characteristics through enhanced impact energy, their fundamental working principle still favors particle elongation compared to true multi-directional crushing systems.

Over-Crushing Rate vs Energy Efficiency Comparison

The comparison of fine particle (0-5mm) generation rates across different crushing mechanisms reveals significant variances in operational efficiency. Impact crushers typically produce 15-25% fines in standard operations, while hammer crushers may generate up to 30-40% due to their repetitive striking mechanism. These differences directly influence downstream processes such as screening efficiency and material handling costs.

When analyzing unit production energy consumption versus wear part economics, impact crushers demonstrate superior cost-effectiveness in medium-hard material processing. Their interparticle crushing principle reduces direct metal-to-material contact, extending wear part life by 30-50% compared to hammer crushers in similar applications. This advantage becomes particularly evident in operations processing abrasive materials or requiring continuous production cycles.

Impact Crusher's Laminated Crushing Energy-Saving Advantages

The interparticle crushing (Interpartikelzerkleinerung) mechanism in impact crushers creates a material bed that absorbs and redistributes crushing forces. This innovative approach significantly reduces over-crushing by allowing particles to break along natural fracture lines, maintaining larger fractions while minimizing powder generation. For limestone processing, this method typically keeps fines below 15% without compromising throughput capacity.

Adjustable impact distance provides another layer of selective breaking capability in modern crushers. Operators can fine-tune the crushing chamber geometry to match material characteristics, optimizing the balance between product gradation and energy consumption. This feature proves invaluable when processing variable feed materials or when specific product specifications must be consistently met.

Hammer Crusher's Secondary Crushing Problems

The hammer crusher's high-speed rotary mechanism subjects materials to repeated impacts, inevitably increasing fine particle generation. Each collision between hammer heads and material creates microfractures that propagate through subsequent strikes, eventually powderizing a significant portion of the feed. The 800-1200 RPM operational range typical for these machines particularly affects brittle materials, potentially doubling fine generation compared to impact crushers.

Material moisture presents unique challenges for hammer crushers, where sticky feed can lead to screen clogging and accelerated wear. The combination of impact forces and material adhesion creates a compounding effect - wet particles adhere to crushing surfaces, reducing effective throughput while increasing energy consumption per ton. Specialized screen designs and modified operating parameters become necessary when processing materials exceeding 8-10% moisture content in hammer crusher configurations.

Practical Guidance for Equipment Selection

Choosing the right stone crusher requires careful evaluation of raw material characteristics such as hardness, moisture content, and clay percentage. Harder materials like granite demand robust crushers with high compressive strength mechanisms, while moist or clay-rich materials may require specialized designs to prevent clogging. For instance, a Impact Crusher excels in handling moderately hard rocks with its efficient impact crushing principle, whereas a Jaw Crusher proves more suitable for primary crushing of extremely hard ores due to its powerful compressive action.

Downstream processing requirements significantly influence crusher selection, particularly when considering final product specifications. Construction aggregate production often prioritizes cubical particle shapes for better compaction, making vertical shaft impact crushers ideal. Mineral processing operations might favor multi-stage crushing circuits with cone crushers for precise size control. The capacity requirements must align with both feed size characteristics and desired discharge dimensions, where parameters like crushing ratio and discharge size become critical selection criteria.

Ideal Scenarios for Impact Crusher Application

Impact crushers demonstrate superior performance in highway aggregate production where strict cubicity requirements exist. The kinetic energy crushing mechanism produces uniformly shaped particles that enhance road surface stability. Their high-speed rotor action fractures materials along natural cleavage planes, resulting in aggregates with excellent interlocking properties crucial for asphalt mixtures and concrete applications.

When processing medium-hard rocks like limestone or dolomite, impact crushers offer notable energy efficiency advantages over compression-style crushers. The adjustable impact plates allow optimization of particle size distribution without significant throughput reduction. For materials containing sticky components, certain EU-type impact crushers incorporate innovative anti-clogging designs through specialized rotor configurations and cascade feeding systems.

Economical Applications of Hammer Crushers

Hammer crushers provide cost-effective solutions for primary crushing of brittle materials such as coal, gypsum, or soft limestone. The simple reciprocating action of hammers against grinding plates delivers high reduction ratios in single-stage operations. This makes them particularly suitable for construction waste recycling projects where irregular particle shapes are acceptable and production scales remain moderate.

Small-scale operators frequently choose PC hammer crushers for their low capital investment and operational simplicity. The minimal foundation requirements and straightforward maintenance reduce overall project costs significantly. However, users must consider higher wear part consumption when processing abrasive materials, as the impact-based crushing mechanism accelerates hammer head deterioration compared to compression crushers.