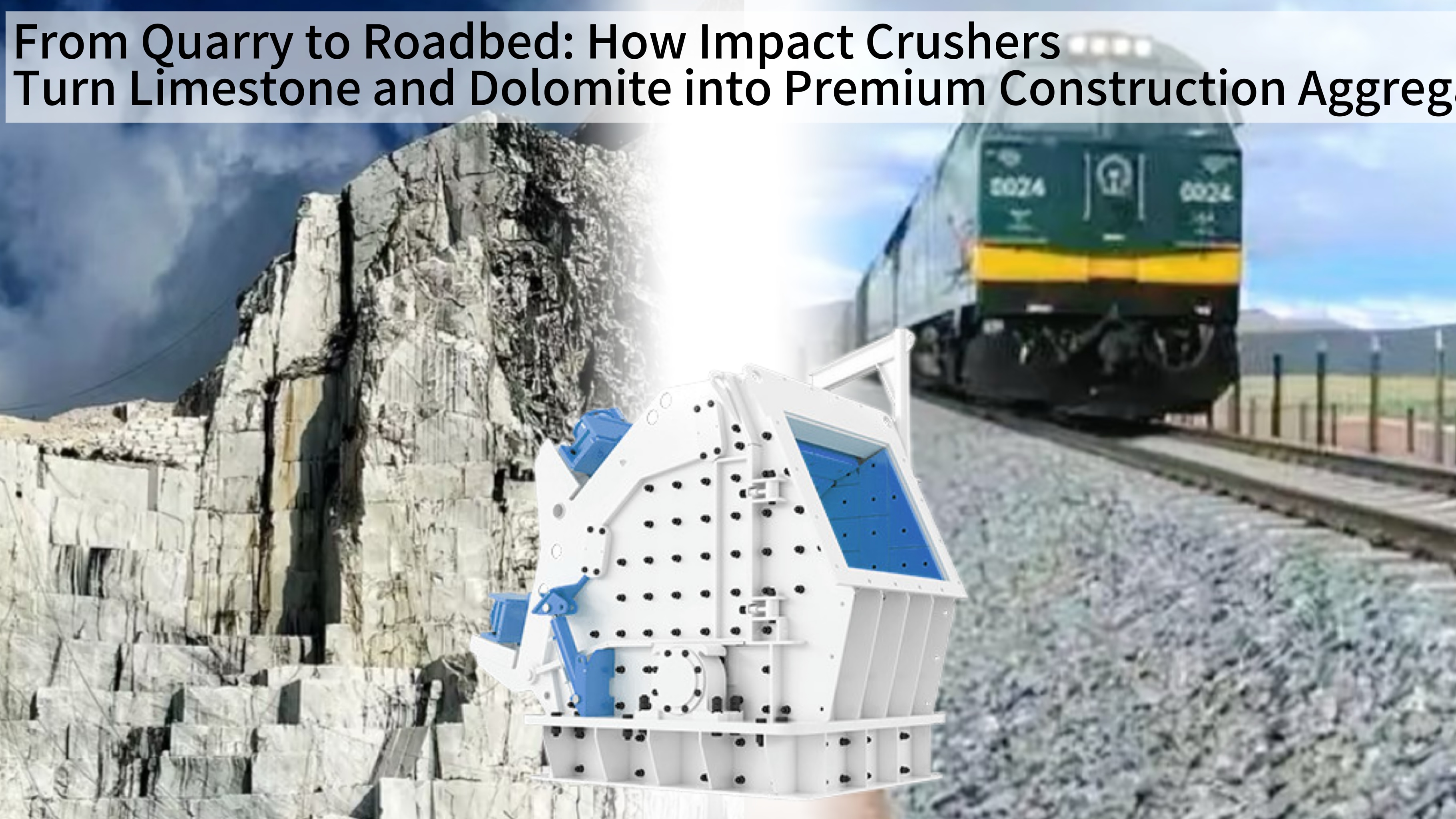

From Quarry to Roadbed: How Impact Crushers Turn Limestone and Dolomite into Premium Construction Aggregate

This guide walks you through every step of using an impact crusher to convert raw limestone and dolomite from the quarry face into the high-quality aggregate that keeps roads strong and smooth. You will learn how the rock’s chemistry and hardness guide machine settings, how feed preparation protects the crusher, how each processing stage is tuned for maximum cubicity and strength, and how modern monitoring keeps costs low while meeting strict engineering standards.

Understanding Limestone and Dolomite: Why an Impact Crusher Fits

Both limestones and dolomites sit in the middle of the hardness scale, yet their subtle differences in grain structure and magnesium content have large effects on fragmentation behaviour. An impact crusher’s ability to deliver controlled kinetic energy and on-the-fly gap adjustments makes it uniquely suited to handle these variations in a single pass.

Chemical and Physical Traits of Limestone

Limestone is composed primarily of calcium carbonate and sits at roughly three to four on the Mohs hardness scale. Its relatively low abrasiveness means that wear parts last longer, but its tendency to cleave along flat planes demands precise rotor speed control to avoid excess fines. The resulting particles are angular and rough-surfaced, locking together tightly under roller compaction to give road bases their load-bearing strength.

Dolomite’s Subtle Strength and Toughness

Dolomite contains significant magnesium carbonate, pushing hardness closer to four and a half and adding a slight toughness that limestone lacks. The extra resilience means the rock absorbs more impact energy before fracturing, so the crusher must run slightly faster and the gaps must be tighter to achieve the same target gradation. Once broken, dolomite grains resist weathering and polish less under traffic, making them ideal for high-grade pavements.

Shared Processing Demands for Mid-Hard Rock

Whether the feed is limestone or dolomite, the goal is to reduce metre-scale blocks to a continuous 5–30 mm gradation with at least eighty percent cubic particles. Continuous feed rates, minimal downtime and low cost per tonne are non-negotiable. An impact crusher’s rotor and adjustable impact plates allow operators to meet these targets without the need for secondary shaping stages.

Comparative Advantages Over Other Crushers

Against jaw-crusher output, impact-crushed grains are already well shaped, reducing the need for further refinement. Compared with cone-crusher circuits, the same tonnage of limestone or dolomite can be processed with roughly fifteen percent less energy and a markedly lower capital outlay. The ability to hydraulically swing the impact plates also compensates for feed variability far faster than manual shim changes on other machines.

Preparing Raw Rock for the Impact Crusher

Blasting, scalping and moisture management at the quarry face determine how smoothly the impact crusher will run. A well-designed front-end sequence keeps oversized boulders, clay and tramp metal away from the rotor, preserving liners and ensuring steady throughput.

Blasting and Primary Sizing

Controlled blasting produces blocks no larger than eighty percent of the feed-port width, typically below eight hundred millimetres. Oversize lumps force the rotor to work harder, spiking current draw and accelerating hammer wear. By matching blast patterns to crusher geometry, operators maintain an even rock stream that fills the crushing chamber without surging.

Removing Clay and Fines

Sticky clay coats rock surfaces and clogs the impact chamber. A vibrating grizzly set at minus five millimetres removes these fines before they reach the crusher, while a drum washer can be installed when clay content exceeds five percent. Keeping feed moisture below eight percent further prevents adhesion, allowing hammers to strike clean, fracture-friendly surfaces.

Parameter Matching for Each Rock Type

For limestone, rotor speeds between nine hundred and twelve hundred revolutions per minute combined with thirty to fifty millimetre breaker gaps deliver the desired gradation without over-grinding. Dolomite demands slightly higher speeds—eleven hundred to fourteen hundred rpm—and narrower gaps to overcome its toughness. An on-board variable-frequency drive lets the operator switch settings within seconds when the feed mix changes.

Fixed versus Mobile Plant Layouts

A stationary plant offers high capacity and tight integration with multiple screens and conveyors, ideal for long-life quarries. A mobile-impact-crusher, however, can follow the face as benches advance, slashing haul distances and fuel costs. The same mobile chassis can be relocated to process stockpiled limestone fines or recycled concrete when quarry output fluctuates.

Impact Crusher Performance on Limestone and Dolomite

The real proof of the process lies in throughput, energy use and product quality. Modern impact crushers consistently deliver high cubicity, low flakiness and uniform gradation while keeping wear costs under tight control.

Particle Shape and Gradation Control

Multiple impact events inside a three-stage chamber knock off corners and edges, producing more than eighty percent cubic grains. Flaky particles remain below eight percent for limestone and below ten percent for dolomite. A single pass can yield a continuous 5–30 mm road-base gradation, eliminating the need for secondary shaping.

Throughput and Energy Efficiency

Typical units process one hundred to three hundred tonnes per hour on limestone at less than five kilowatt-hours per tonne, and up to six and a half kilowatt-hours per tonne on tougher dolomite. Rotor diameters between twelve hundred and fifteen hundred millimetres paired with one-hundred-sixty to three-hundred-fifteen kilowatt motors provide ample kinetic reserve for sticky feeds or sudden surges.

Process Flexibility and Multi-Spec Output

Hydraulic adjustment of the impact plate gap allows the same machine to shift from coarse 20–30 mm base layer material to finer 5–10 mm sub-base within thirty seconds. Variable rotor speed further trims the fraction of minus-five-millimetre fines to a stable ten to fifteen percent, making downstream screening easier.

Total Cost of Ownership

Capital cost for an impact crusher line is roughly twenty to thirty percent lower than an equivalent cone circuit, while combined wear-part and energy costs run fifteen to twenty-five percent lower. Over a 200 000-tonne annual programme, savings can exceed half a million dollars, and resale values after five years remain above thirty percent of original investment.

Step-by-Step Flow from Quarry Face to Stockpile

Each stage builds on the previous to safeguard quality. Oversight is continuous, from blast hole layout to final moisture checks in the covered stockyard.

Coarse Breaking and Size Control

A primary jaw-crusher reduces run-of-mine rock to less than two hundred millimetres, creating a consistent feed for the impact crusher. Gap settings on the jaw are monitored daily to prevent oversized lumps from overloading the rotor.

Secondary Crushing and Cubic Shaping

The impact crusher now operates at its designed speed—twelve hundred to fifteen hundred revolutions per minute—while breaker plates are set at fifteen to thirty millimetres to match the desired 5–30 mm product. Belt scales transmit live tonnage data to the control room, allowing operators to tweak feed rate and rotor load in real time.

Sizing, Washing and Recirculation

Two- or three-deck vibratory screens separate 5–10 mm, 10–20 mm and 20–30 mm fractions. Oversize above thirty millimetres is conveyed back to the impact crusher, keeping recirculation below fifteen percent. A light spray bar removes adhering dust without saturating the product.

Storage and Final Quality Checks

Each fraction is stored in separate bays to prevent segregation. Ambient air drying keeps moisture below six percent, satisfying compaction specifications. Every eight-hour shift, technicians run sieve analyses, flakiness index tests and Los Angeles abrasion checks, feeding any deviations back to the control room for immediate crusher adjustment.

Meeting Engineering Standards for Road-Base Aggregate

Highway agencies specify tight limits on gradation, flakiness and durability. The impact crusher’s adjustable energy and residence time make it straightforward to stay within these limits regardless of natural rock variability.

Gradation Continuity and Void Ratio

Target void ratios below thirty-five percent require a smooth gradation curve. Operators can tilt the impact plate by plus or minus five degrees to fine-tune the proportion of mid-sized fractions. Continuous belt sampling every eight hours confirms compliance before trucks leave the yard.

Aggregate Crushing Value and Strength

Highway specifications cap the aggregate crushing value at twenty percent. Impact crushing yields values eighteen percent or lower for limestone and twenty-two percent or lower for dolomite—five to eight percent better than jaw-only products—because the controlled impact energy creates fewer hidden micro-cracks.

Flakiness Index Control

For expressways, flakiness must stay below fifteen percent; for secondary roads, below twenty percent. A high-speed, small-gap setting—fourteen hundred revolutions per minute with twenty-millimetre gaps—keeps dolomite flakes under control while maintaining throughput.

Contaminant Removal and Cleanliness

Clay and sulphate limits are met by pairing the impact crusher with a limestone-crushing wash plant when feed contamination exceeds one percent. Online turbidity meters cut wash-water use by only activating sprays when needed, conserving both water and energy.

Case Studies and Economic Validation

Real-world projects confirm the theoretical advantages and provide templates that can be replicated in new quarries or mobile operations.

High-Speed Highway Base Course Project

A 500–1000 mm limestone feed is broken in a two-stage circuit: one jaw and two parallel PF-1315 impact crushers feeding a three-deck screen. Daily output reaches eight hundred tonnes with eighteen percent crushing value and twelve percent flakiness, meeting expressway standards while cutting processing cost to twenty-eight dollars per tonne—seven dollars lower than a jaw-plus-cone alternative.

Rural Road Dolomite Production

A mobile impact plant processes 300–600 mm dolomite blocks at three hundred tonnes per day. The tracked chassis eliminates thirty percent of haul distance, and the finished aggregate satisfies local road specifications with twenty-two percent crushing value and continuous gradation.

Mixed Feed Processing Strategy

When limestone and dolomite are blended in a 7:3 ratio, a variable-frequency motor allows rotor speed to swing between 1100 and 1500 r/min as hardness fluctuates. Real-time camera analysis on the conveyor keeps flakiness below fifteen percent across the blend, enabling a layered road design that places tougher dolomite at the base for enhanced moisture resistance.

Comparative Economic Summary

Across all studied sites, payback periods for impact-crusher lines averaged 1.5 to 2 years versus 2.5 to 3 years for conventional circuits. Energy savings of fifteen to twenty percent on limestone and ten to fifteen percent on dolomite, combined with higher product acceptance rates above ninety-five percent, delivered clear financial and environmental dividends.

Equipment Selection and Parameter Tuning

Matching machine size, rotor speed and wear materials to rock characteristics ensures reliable output and predictable maintenance schedules.

Capacity-Driven Model Selection

Small quarries processing 50–100 t/h can rely on the PF-1210 with its 1200 mm rotor. Mid-range 100–300 t/h operations favour the PF-1315, while large 300 t/h-plus plants use the PF-1520 or parallel units. A twenty percent capacity buffer is recommended to absorb feed variability without overloading motors.

Optimised Settings for Limestone

For limestone, rotor speeds of 1200–1300 r/min combined with primary gaps of 25–35 mm and secondary gaps of 15–25 mm balance throughput and shape. High-manganese hammers resist the moderate abrasion while offering good impact toughness.

Optimised Settings for Dolomite

Dolomite demands slightly higher speeds—1300–1500 r/min—and narrower gaps of 20–30 mm primary and 10–20 mm secondary. Chrome-moly hammers extend service life by thirty percent, and impact plates angled at 35–40° increase collision frequency to refine particle edges.

Auxiliary Systems and Safety

Pulse-jet dust collectors rated at ten thousand cubic metres per hour keep respirable dust below ten milligrams per cubic metre. Automatic central lubrication delivers oil to bearings every hour, while PLC screens integrate motor current, rotor speed and throughput data for at-a-glance diagnostics. Overload relays and emergency stops safeguard both operators and machinery.

Future Trends in Impact Crushing for Road-Base Aggregate

Advances in automation, sustainability and modular design are pushing impact crushers toward smarter, greener and more flexible roles in quarry operations.

Self-Adaptive Control and Remote Maintenance

Machine-vision cameras will soon measure every particle on the discharge belt, automatically adjusting impact-plate gaps to maintain shape index targets. Cloud-connected sensors will stream vibration and temperature data to service teams, shifting maintenance from reactive to predictive and pushing uptime beyond ninety-eight percent.

Energy and Environmental Upgrades

Hybrid electric-diesel drives will shave peak power demand, while fully enclosed crushing chambers and high-efficiency filters will cut particulate emissions to ten milligrams per cubic metre. Recycled concrete and asphalt containing limestone fragments will be re-processed on the same impact platform, closing the material loop.

Structural Innovations for Mid-Hard Rock

Modular chamber cartridges will allow operators to swap from limestone to dolomite profiles in under an hour. Ceramic-metal composite hammers promise fifty percent longer life, and lightweight rotors reduce start-up inertia, saving both fuel and generator load when operating in remote quarries.

Process Integration from Quarry to Road

Future mobile plants will share live gradation data with paving machines, enabling real-time mix adjustments. The vision is a tracked impact crusher that follows the excavation face, crushes, screens and immediately feeds an on-site paver—cutting project timelines by thirty percent and eliminating stockpile double handling.