STONE CRUSHER

Stone Crusher (also named Rock Crusher or Ore Crusher) is a heavy mining machine that breaks down large rocks into smaller, usable pieces. This heavy-duty equipment handles various materials including natural stones like granite and basalt, metal ores such as iron and copper, and recycled construction materials like concrete rubble. The stone crusher works by applying strong forces - through crushing, hitting, or grinding actions - to reduce materials to specific sizes (typically between 5mm and 150mm) perfect for construction, mining, or recycling uses.

The stone crushers from MSW Group integrate cutting-edge technologies, including an AI-powered central processing system, optional electric or diesel engine drives, crushing chambers with wear-resistant liners, safety alert systems to prevent damage from uncrushable materials, and adjustable settings for controlling final product size. These unique designs enable the stone crushers to operate efficiently with low energy consumption and smooth performance across various applications: processing raw ore in mining operations, producing aggregates for foundations and road construction projects, and transforming waste into valuable resources in recycling plants.

Types of Stone Crusher

Different stone crushers have different application scenarios. Choosing the right machine can help you complete the task better.

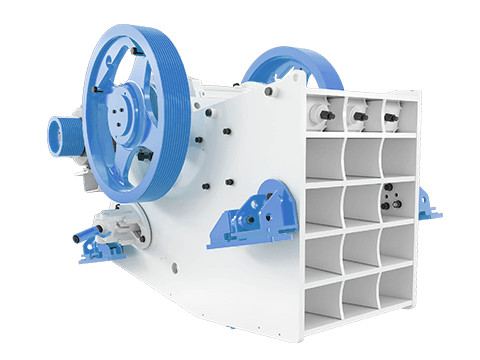

Jaw Crusher

Compressive Crushing: Utilizes compressive force generated by a reciprocating motion between a fixed jaw plate and a movable jaw plate. The material is crushed by progressive compression as it moves downward through the crushing chamber.

Primary Crushing High Reduction Ratio

Learn more >>

Cone Crusher

Employs interparticle crushing (also called layer compression), where rocks are crushed between a rotating mantle and a concave liner. The eccentric gyratory motion of the mantle creates a compressive force field, inducing fractures along grain boundaries.

Secondary Crushing Hydraulic Adjustment

Learn more >>

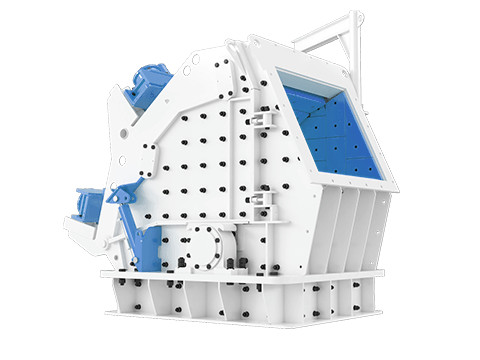

Impact Crusher

Dynamic Impact Crushing: Relies on kinetic energy transfer via high-speed rotors equipped with blow bars or hammers. Material is shattered by direct impact against rotating components or stationary anvils, with fragmentation occurring through particle-on-particle collisions.

High-Speed Impact Cubical Aggregate

Learn more >>

Roll Crusher

Shear-Compression Crushing: Applies shear-compression forces between counter-rotating rolls with textured or smooth surfaces. Material is drawn into the gap (nip angle) and fragmented via tensile failure or surface abrasion.

Double Roll Design Low Fines Production

Learn more >>

Hammer Crusher

Dynamic Impact with Grinding: Combines high-velocity hammer strikes (rotating hammers on a horizontal shaft) with material grinding against breaker plates or screens. Fragmentation occurs through impact, attrition, and shear.

High-Speed Hammer Brittle Material Crushing

Learn more >>

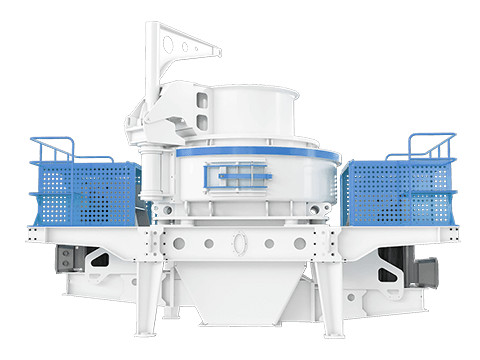

VSI Crusher

Centrifugal Acceleration Crushing: Accelerates material through a high-speed rotor (up to 70 m/s) and projects it against a stationary anvil or rock-lined chamber, exploiting centrifugal force and interparticle collision for fragmentation.

Vertical Shaft Impact Cubical Product Shape

Learn more >>

Gyratory Crusher

Conical Compression Crushing: Operates via a conical head gyrating within a concave bowl, generating progressive compression as material moves downward. Combines elements of jaw and cone crushers for ultra-high-capacity primary crushing.

Primary Crushing High Capacity

Learn more >>

Fine Crusher

With a simplified structure and convenient maintenance, Fine Crusher delivers high production capacity and a long service life for its hammer heads. It is widely used for crushing granite, basalt, limestone, river pebbles, cement clinker, quartz stone, iron ore, bauxite, and more.

Precision Crushing Ultra-Fine Output

Learn more >>

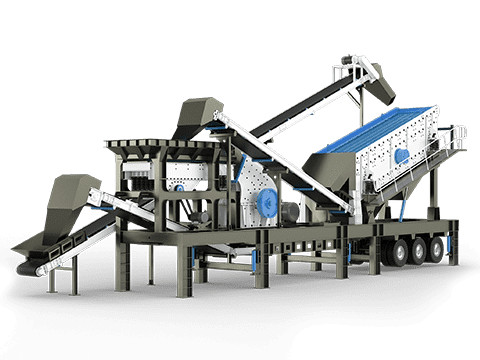

Mobile Crusher

Mobile crushers are advanced crushing machines designed for on-site material processing, offering high mobility and flexibility. They can be easily transported between job sites, making them ideal for construction, mining, and recycling applications.

On-Site Crushing Track / Wheel Mobility

Learn more >>

Mining and Quarrying

Our crushing solutions for mining and quarrying deliver high-performance equipment designed to handle the toughest materials, from hard rock to abrasive ores. With advanced jaw, cone, and gyratory crushers, we ensure efficient primary, secondary, and tertiary crushing for optimal mineral extraction and processing.

Learn more >>

C&D Waste Recycling

Transform construction and demolition waste into valuable resources with our mobile and stationary crushing systems. Our solutions enable on-site recycling of concrete, bricks, and asphalt, reducing landfill use and promoting sustainable construction practices.

Learn more >>

Aggregate Processing

From natural rock to recycled materials, our aggregate processing solutions produce high-quality sand, gravel, and crushed stone for construction projects. With precision crushing and screening, we ensure consistent gradation and superior particle shape for concrete and asphalt applications.

Learn more >>

Cement Manufacturing

Optimize your cement production process with our crushing solutions tailored for limestone, clay, and other raw materials. Our robust crushers ensure uniform feed size, enhancing grinding efficiency and reducing energy consumption in cement manufacturing.

Learn more >>

Typical Three-Stage Stone Crushing Process

To produce high-quality aggregates, the following Three-Stage stone crushing process is commonly used:

- Primary Crusher → Crushes raw stones into 200mm - 400mm particles.

- Secondary Crusher → Reduces material size to 40mm - 100mm.

- Tertiary Crusher → Further crushes the material to 0-40mm or even finer.

Function: Handles the first stage of crushing, reducing large rocks into smaller pieces.

Common Types:

- Jaw Crusher – Suitable for hard and abrasive materials.

- Gyratory Crusher – Ideal for high-capacity applications.

- Impact Crusher – Sometimes used for softer stones like limestone.

Features: Large feed size (500mm - 1500mm), high capacity, mainly used in mining and quarrying.

Function: Further reduces the size of materials after primary crushing, ensuring uniform particles.

Common Types:

- Cone Crusher – Excellent for hard and medium-hard materials.

- Impact Crusher – Used when shaping is required.

- Roll Crusher – For medium-hard and brittle materials.

Features: Handles feed sizes of 100mm - 400mm, produces well-shaped aggregates.

Function: Provides final crushing to refine material into fine particles, often used for sand production.

Common Types:

- VSI Crusher – Used for producing high-quality manufactured sand.

- Fine Crusher – Further refines aggregates.

- High-Efficiency Cone Crusher – Provides finer crushing results.

Features: Handles 20mm - 100mm feed size, improves final product quality.

How to Choose the Right Stone Crusher?

Choosing the best stone crusher makes a huge difference in your crushing efficiency. Here's what to look for:

- Crushing power - How well it breaks down large rocks into smaller pieces

- Rock size handling - Maximum boulder size the crusher can accept

- Final stone size - The crushed material sizes you need for your project

- Processing speed - How many tons of material it can crush per hour

The crushing power shows how effectively a stone crusher reduces large rocks. More powerful crushers work great for multiple crushing steps. Always check that your machine can handle your biggest rocks while still producing the exact crushed sizes you need.

Different stone crushers work best for different jobs:

- Jaw crushers - Best for first-stage crushing of very large rocks

- Cone crushers - Perfect for creating precise, smaller stone sizes

Match your stone crusher to both your material type (like granite or limestone) and your project needs (mining or construction) to get the best results at the lowest cost. The right choice means more productivity and better crushed stone for your operation.

| Crusher Type | Advantages | Disadvantages | Application | Suitable Materials | Output Size |

|---|---|---|---|---|---|

| Jaw Crusher | Simple structure, durable, easy maintenance, suitable for primary crushing | Large output size, requires secondary crushing, low efficiency | Mining, construction, metallurgy | Granite, basalt, ores | 100-300mm |

| Cone Crusher | High crushing efficiency, good particle shape, less wear, suitable for secondary and fine crushing | Complex structure, high cost, not suitable for sticky materials | Mining, sand production | Granite, pebbles, iron ore | 5-50mm |

| Impact Crusher | Large crushing ratio, uniform output size, suitable for medium-hard materials | Fast wear of parts, not suitable for high-hardness materials | Building materials, mining, metallurgy, chemicals | Limestone, concrete, coal | 10-50mm |

| Hammer Crusher | Simple structure, one-time forming, high crushing ratio | High wear parts consumption, limited application range | Medium-hard and brittle materials | Coal, gypsum, limestone | 5-50mm |

| Mobile Crusher | High mobility, suitable for on-site operations, saves transportation costs | Limited processing capacity, high cost | Construction waste, mining, road engineering | Various materials | 5-100mm |

| Fine Crusher | High efficiency, small output size, suitable for sand production | High energy consumption, relatively low output | Sand making, building materials | Limestone, pebbles, granite | 0-5mm |

Essential Tips for Maintaining Your Stone Crusher

Keep Your Stone Crusher Running Smoothly

Taking care of your stone crusher helps it last longer and work better with less breakdown time.

Key Parts to Check Regularly:

- Crushing area (crushing chamber) - Look for worn spots that might slow down crushing

- Crushing surfaces (jaw plates and others) - Replace when worn to keep crushing power strong

- Protective liners (liner plates) - Change these to control the size of crushed stones

- Hitting parts (blow bars) - Important for impact crushers to work right

Other Important Checks:

- Look for cracks in the pressure plate

- Keep the main turning shaft oiled to avoid getting too hot

- Make sure spinning parts (hammer heads) are balanced and not worn out

- Clean the heavy wheel (flywheel) that keeps the crusher running steady

Why Maintenance Matters for Your Stone Crusher

Good care of your stone crusher means:

- More years of reliable service

- Better crushing power

- Lower repair costs

- Fewer work stoppages

- Safer operation

Simple, regular checks can make your stone crusher work better while keeping your workers safe.

Why Choose Our Stone Crusher

Customized crusher with reliable price

We offer more than just stone crushers—we provide complete solutions tailored to your specific needs. With years of experience in the industry, we have developed cutting-edge technology and engineering expertise to deliver reliable, high-performance crushers that are built to last. Our commitment to quality and innovation ensures that you receive equipment that maximizes efficiency, minimizes downtime, and reduces operational costs.

Latest Knowledge about Stone Crushers

Read more about stone crushers and related topics written by our experts.

Impact Crusher: Advanced Impact Crushing Solutions for Diverse Industrial Needs

Guide to Impact Crusher + Vibrating Screen Process Flow for Asphalt Pavement Processing

Comprehensive Energy Optimization Guide for Mobile Jaw Crushers at Demolition Sites

Mobile Jaw Crusher: 2025 Global Guide to Sustainable Crushing Technology and Applications

AI Ore Sorting Crusher Revolution: Cutting 30 % Energy with Smart Pre-screening & Targeted Fracture

Stone Crusher Guide: Principles, Optimization & 200% Efficiency Strategies

Contact Us

Don't know how to choose? Need more detail? Contact us to provide you with customized services. Our specialist will be at your service.