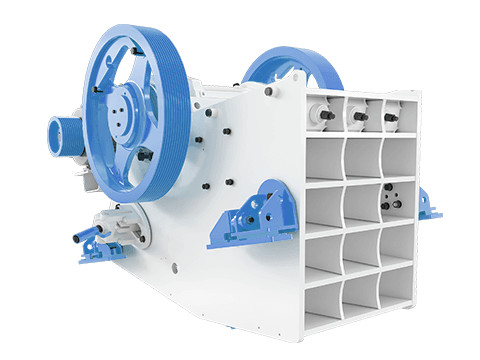

JC Serial Crushers

JC series crushers represent an advanced generation of jaw crushers, designed to provide superior performance, durability, and efficiency. These crushers incorporate cutting-edge technology and innovative design features to enhance crushing capacity and reliability. Widely used in mining, construction, and aggregate industries, JC series crushers offer improved crushing efficiency and operational stability. In this article, we will explore the characteristics, benefits, and applications of JC series crushers, emphasizing their role in modern material processing.

Introduction to JC Series Crushers

JC series crushers are a modern evolution of traditional jaw crushers, featuring an optimized design for enhanced efficiency and performance. These crushers use a deep crushing chamber and a reinforced frame to handle high-strength materials effectively. With improved structure and components, JC series crushers are engineered to deliver exceptional crushing results with minimal energy consumption.

Advanced Design and Structural Strength

The structural design of JC series crushers enhances their ability to withstand heavy loads and continuous operation. Made from high-quality steel and reinforced with precision engineering, these crushers exhibit superior resistance to wear and impact. The optimized frame structure minimizes vibration and enhances stability, ensuring reliable performance in demanding environments.

Higher Crushing Efficiency and Productivity

One of the standout features of JC series crushers is their ability to achieve higher crushing efficiency. Their deep crushing chamber allows for better material intake and improved reduction ratios, resulting in finer and more uniform crushed products. The advanced toggle plate system and efficient power transmission mechanism contribute to increased productivity and reduced energy consumption.

Versatility Across Different Applications

JC series crushers are suitable for a wide range of applications, including mining, aggregate production, and construction waste recycling. They can efficiently process hard rock, ores, and various mineral aggregates, making them an ideal choice for primary and secondary crushing operations. Their adaptability allows industries to optimize material processing and enhance overall production efficiency.

Durability and Low Maintenance Requirements

Durability is a key advantage of JC series crushers, as they are built to withstand tough operating conditions. Their wear-resistant components and precision-engineered parts extend their service life, reducing the frequency of repairs and maintenance. Additionally, the simplified maintenance process ensures minimal downtime, contributing to increased operational efficiency.

Innovative Technology for Enhanced Performance

JC series crushers incorporate advanced technological features to enhance their performance. Hydraulic adjustment systems allow for quick and easy setting modifications, ensuring optimal output size control. Some models also feature intelligent monitoring systems that provide real-time data on crusher performance, enabling operators to optimize operations and prevent potential issues.

Why Choose JC Series Crushers?

JC series crushers offer a combination of strength, efficiency, and advanced technology, making them a preferred choice for industries requiring high-performance crushing solutions. Their ability to process various materials with precision and reliability ensures consistent output quality. Whether used in mining, construction, or aggregate processing, JC series crushers provide a durable and efficient solution for demanding crushing applications.