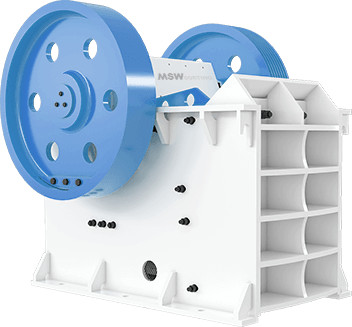

PE Serial Crushers

PE series crushers are widely used in the mining, construction, and aggregate industries due to their reliability, high efficiency, and ability to process a variety of materials. These crushers are designed to handle tough crushing applications while maintaining excellent performance over time. Their simple yet robust structure makes them an ideal choice for primary crushing operations. In this article, we will explore the features, advantages, and applications of PE series crushers, highlighting their role in modern material processing.

Overview of PE Series Crushers

PE series crushers are jaw crushers that utilize a simple yet effective mechanism for crushing hard and abrasive materials. These crushers feature a fixed and a movable jaw that work together to reduce large rocks into smaller, manageable sizes. Their design prioritizes durability and efficiency, making them a preferred choice for heavy-duty crushing operations in mining and industrial applications.

Key Features of PE Series Crushers

One of the defining characteristics of PE series crushers is their sturdy construction. Made from high-quality steel, these machines can withstand extreme pressure and heavy workloads. Additionally, PE series crushers are equipped with powerful motors that ensure consistent crushing performance. Their deep crushing chamber design enhances efficiency by allowing for a greater feed size and improved material reduction.

Advantages of PE Series Crushers

PE series crushers offer numerous advantages, making them a top choice in material processing industries. They provide high crushing efficiency, which allows for rapid material breakdown and increased productivity. Their simple structure ensures easy maintenance, reducing downtime and operational costs. Furthermore, these crushers exhibit strong adaptability, allowing them to process a wide range of materials, from hard rock to softer minerals.

Applications in Various Industries

PE series crushers are extensively used in various industries, including mining, metallurgy, construction, and road building. In mining operations, they serve as primary crushers, breaking down large ore blocks before further processing. In the construction sector, they are used to crush concrete, bricks, and other building materials. Their versatility also makes them suitable for aggregate production, ensuring high-quality crushed materials for infrastructure projects.

Durability and Long Service Life

Durability is a key factor in the success of PE series crushers. Their robust frame and wear-resistant components contribute to an extended service life, even under harsh working conditions. Regular maintenance and timely replacement of wear parts further enhance their longevity, making them a cost-effective investment for long-term crushing operations.

Efficiency and Performance Optimization

The efficiency of PE series crushers can be optimized through proper installation and operation. Adjusting the jaw plate settings and ensuring even feeding contribute to improved performance and reduced energy consumption. Additionally, incorporating advanced automation features can further enhance operational efficiency by reducing manual intervention and maximizing output.

Why Choose PE Series Crushers?

PE series crushers are a reliable solution for demanding crushing applications. Their combination of high performance, durability, and ease of maintenance makes them an excellent choice for industries requiring consistent and efficient material processing. With their proven track record in various sectors, PE series crushers continue to be a preferred option for crushing solutions worldwide.