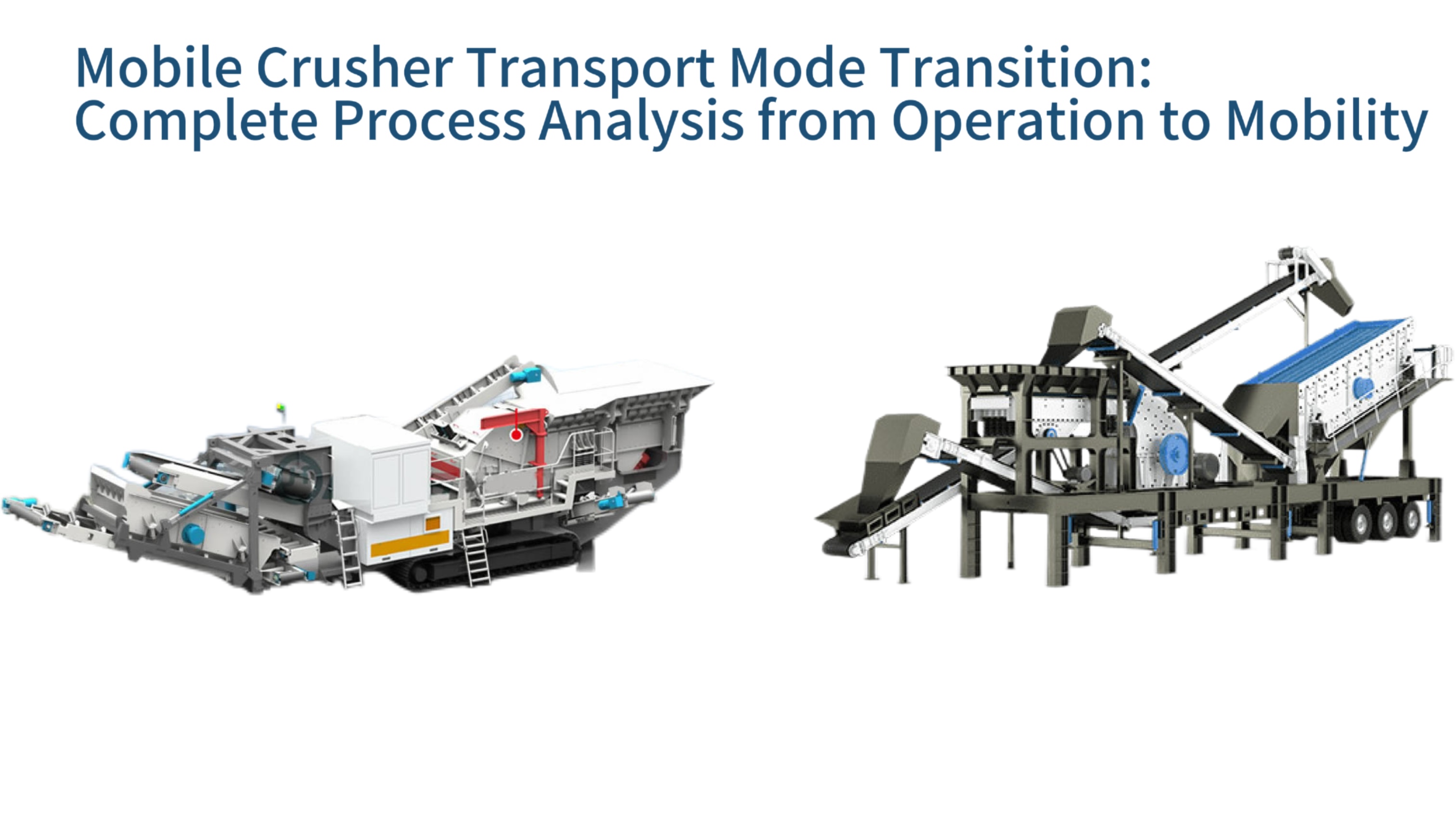

Mobile Crusher Transport Mode Transition: Complete Process Analysis from Operation to Mobility

This comprehensive guide examines the technical transformation process of mobile crushing equipment between operational and transport configurations. We'll explore the systematic procedures, safety protocols, and engineering innovations that enable rapid site transitions while maintaining equipment integrity. Discover how modern mobile crushers achieve remarkable mobility without compromising performance or safety standards.

Core Value and Application Scenarios of Transport Mode Conversion

Efficient configuration switching significantly impacts project economics and operational flexibility. Modern mobile crushers can transform between working and transit states within 60-90 minutes, enabling contractors to respond dynamically to changing project requirements. This adaptability proves especially valuable in multi-phase construction projects where equipment must frequently relocate between different work zones.

Project Cycle Characteristics Analysis

Construction projects typically progress through sequential phases requiring different material specifications. Mobile crushers adapt to these changing demands through rapid reconfiguration. The transition capability aligns equipment utilization with project timelines, preventing costly idle periods between project stages.

Different crushing configurations produce specific aggregate gradations needed for various construction phases. Quick mode switching ensures continuous material supply matching each phase's requirements without equipment downtime.

Transport Cost and Operational Time Balance Model

Optimized conversion procedures minimize non-productive time while reducing transportation expenses. Efficient transitions decrease the need for specialized transport equipment, lowering overall project costs. The economic balance considers fuel consumption, labor costs, and potential revenue loss during conversion periods.

Advanced mobile crushing systems incorporate time-motion studies to streamline each transition step. This optimization reduces conversion time by 25-40% compared to traditional systems, significantly improving project economics.

Comprehensive Pre-Transition Preparation

Thorough preparation ensures safe and efficient configuration changes. This phase involves systematic equipment checks and safety procedures that prevent damage during transformation. Proper preparation minimizes the risk of component failure during transit and ensures operational readiness at the next site.

Crushing Plate Wear Assessment Standards

Wear measurement protocols determine when components require replacement before relocation. Laser scanning technology creates 3D models of wear surfaces, comparing them against original specifications. This digital analysis identifies components needing replacement before transport mode activation.

Worn components increase vibration during transit, potentially causing structural damage. Replacement thresholds vary by material hardness and operational hours, with typical replacement intervals between 500-800 operational hours for granite processing.

Hydraulic Circuit Pressure Release Procedure

Controlled pressure reduction prevents hydraulic system damage during disassembly. Sequential valve opening follows manufacturer-specified sequences to avoid pressure spikes. This gradual release protects sensitive components like control valves and pressure sensors.

Residual pressure indicators confirm complete system depressurization before disconnecting hydraulic lines. Technicians verify zero-pressure status at multiple test points, ensuring personnel safety during subsequent disassembly steps.

Conveyor Belt Tension Adjustment Methodology

Proper tensioning prevents belt deformation during extended transport. Digital tension gauges measure force at strategic points along the belt path. Adjustments follow manufacturer specifications based on belt length and material composition.

Belt relaxation prevents permanent deformation during transit while maintaining structural integrity. Proper tensioning extends belt life by reducing stress concentrations at connection points during transport vibration.

Physical Configuration Transformation

Mechanical reconfiguration involves precise movements of major components to achieve transport dimensions. This phase transforms the equipment profile from operational spread to compact transit configuration. Engineering precision ensures structural integrity while minimizing transport dimensions.

Conveyor System Folding Technique

Articulated conveyor sections fold according to predefined geometric constraints. Hydraulic actuators position segments at calculated angles to maximize space efficiency. This folding sequence considers both transport dimensions and component stress limitations.

Interlocking mechanisms secure folded sections during transit. These specialized latches withstand vibration forces up to 3G while allowing quick redeployment. Proper folding reduces transport width by 40-60%, enabling road compliance.

Crusher Elevation Positioning Control

Hydraulic cylinders elevate the crushing assembly to achieve optimal transport height. Position sensors provide real-time feedback to the control system, ensuring precise alignment. This elevation reduces the machine's center of gravity for improved transport stability.

The lifting sequence maintains structural balance throughout the operation. Counterweight systems prevent uneven stress distribution that could damage frame components. Final position verification ensures adequate ground clearance for anticipated transport routes.

Electrical Control System Reconfiguration

Electronic systems undergo comprehensive reprogramming for transport safety and monitoring. This transformation involves mode-specific parameter sets that optimize different operational states. System reconfiguration ensures continuous monitoring capabilities during transit while conserving energy.

PLC Program Transition Protocol

Control systems automatically switch between operational and transport logic modules. This transition deactivates production-related functions while activating transport monitoring systems. The reprogramming sequence includes comprehensive self-diagnostics to verify successful mode change.

Transport mode programming prioritizes safety interlocks and diagnostic monitoring. Critical functions like vibration detection and temperature monitoring remain active with modified sensitivity thresholds appropriate for transit conditions.

Wireless Control Frequency Adjustment

Communication systems switch to transport-optimized frequencies with extended range capabilities. This adjustment maintains control link integrity during long-distance transport. Frequency-hopping protocols prevent interference during highway transit through varied signal environments.

Encryption protocols activate during transport to secure operational data and location information. These security measures protect sensitive operational parameters while ensuring continuous remote monitoring capabilities.

Safety Verification and Compliance Inspection

Rigorous safety checks ensure roadworthiness and regulatory compliance before transport. This phase combines physical measurements with functional testing to verify transit readiness. Compliance documentation is generated automatically for regulatory verification.

3D Scanning for Dimension Verification

Laser measurement systems create digital twins of the transport configuration. This scanning compares actual dimensions against regulatory limits with millimeter precision. Automated reporting flags any compliance issues before transport initiation.

The scanning process verifies clearance heights, width restrictions, and overhang limits simultaneously. This comprehensive check prevents costly route violations and ensures safe passage under bridges and through tunnels.

Center of Gravity Analysis for Transport Stability

Dynamic weight distribution calculations determine optimal load positioning. This analysis considers fuel levels, component positions, and accessory equipment to calculate precise center of gravity coordinates. The results guide securement point selection and transport speed limitations.

Stability simulations predict performance under various transport conditions including sharp turns and emergency braking scenarios. These models ensure safe handling characteristics within defined operational parameters.

Transport Monitoring Systems

Continuous monitoring during transit provides real-time equipment status and security. Advanced sensor networks detect potential issues before they become critical problems. This monitoring ensures equipment integrity throughout the transport phase.

Position Tracking Data Optimization

GPS systems adjust reporting frequency based on transport conditions. In urban areas, position updates occur every 15 seconds, while highway transit uses 60-second intervals. This optimization balances data accuracy with communication bandwidth efficiency.

Geofencing technology creates virtual boundaries around transport routes. Automatic alerts trigger if equipment deviates from planned paths, enhancing security against unauthorized movement.

Critical Component Temperature Surveillance

Infrared sensors monitor bearing temperatures throughout transit. This continuous monitoring detects abnormal friction buildup that could indicate developing mechanical issues. Temperature trends predict potential failures before they occur.

Wireless sensor networks transmit temperature data via low-power protocols. This energy-efficient approach maintains monitoring capabilities throughout extended transport durations without draining battery systems.

Rapid Redeployment at New Sites

Efficient reactivation transforms equipment from transport to operational configuration quickly. This process reverses transition procedures with site-specific adjustments for immediate productivity. Proper deployment ensures operational readiness within minimal timeframes.

Site Evaluation for Equipment Placement

Ground penetration radar assesses subsurface stability before positioning heavy equipment. This non-invasive scanning identifies potential settling issues or underground obstructions. The analysis determines optimal crusher placement for both stability and operational efficiency.

Topographic mapping creates digital elevation models for proper water drainage planning. This prevents operational disruptions due to flooding or material washout during precipitation events.

Crushing Parameter Initialization Protocol

Material-specific presets configure operational parameters automatically. These settings include feed rates, rotor speeds, and discharge settings optimized for the new site's material characteristics. The system recalls previous configurations for similar material types.

Automated calibration sequences verify crusher settings before operation. Laser alignment checks ensure proper clearances while vibration analysis confirms balanced operation at various speed settings.