Mobile Jaw Crusher

Mobile jaw crushers are powerful and efficient crushing machines designed for on-site material processing. With high mobility and versatility, they are widely used in construction, mining, and recycling applications.

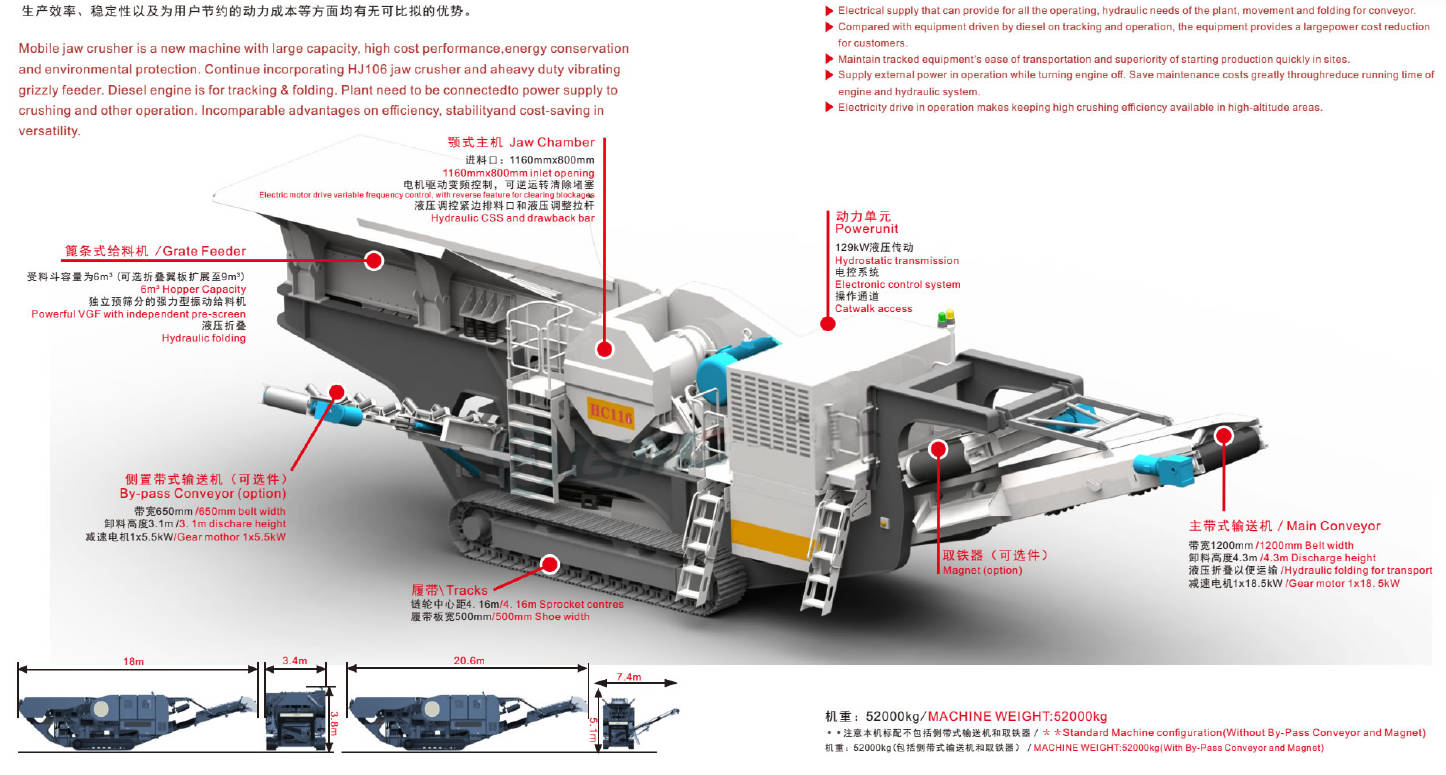

Features of Mobile Jaw Crusher

Mobile jaw crushers are equipped with a robust jaw crushing unit, a conveyor system, and a mobile chassis. Their compact design allows for easy transportation and quick setup at different job sites.

Advantages of Mobile Jaw Crusher

One of the main advantages of mobile jaw crushers is their ability to crush materials directly at the source, reducing transportation costs and increasing operational efficiency. They also offer adjustable settings for different material requirements.

Applications of Mobile Jaw Crusher

Mobile jaw crushers are widely used in industries such as construction, mining, demolition, and recycling. They are ideal for processing hard rocks, concrete, asphalt, and other tough materials on-site.

Key Components of Mobile Jaw Crusher

The main components of a mobile jaw crusher include the jaw crusher unit, a vibrating feeder, a discharge conveyor, and a track or wheeled chassis. Each component plays a crucial role in delivering efficient crushing performance.

Comparison with Stationary Jaw Crusher

Unlike stationary jaw crushers, mobile jaw crushers provide superior flexibility and mobility. They can be moved to different locations, making them ideal for temporary projects or operations requiring frequent site changes.

Maintenance Considerations for Mobile Jaw Crusher

Regular maintenance tasks include checking wear parts, lubricating moving components, and inspecting the jaw plates for damage. Proper upkeep ensures the crusher runs smoothly and extends its operational lifespan.