Multi-Cylinder Hydraulic Cone Crushers: Optimizing Metal Mine Tertiary Crushing

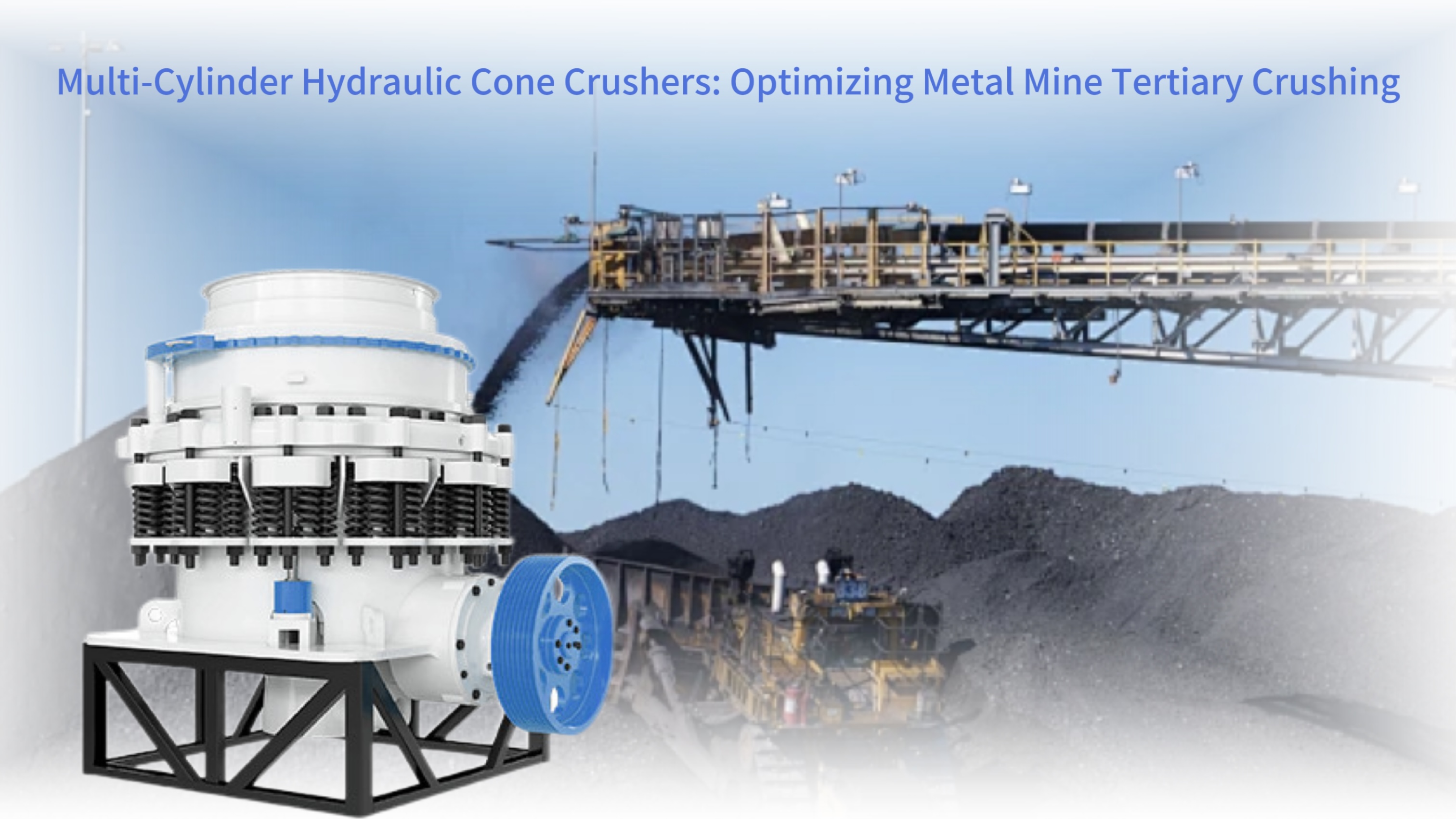

Tertiary crushing represents a critical stage in metal ore processing where mineral liberation directly impacts recovery rates. Multi-cylinder hydraulic cone crushers have emerged as the preferred solution for this demanding application due to their precision control and robust construction. This comprehensive guide examines how these advanced machines transform coarse ore fragments into optimally sized particles ready for grinding circuits. We'll explore equipment selection methodologies, operational parameter optimization, system integration strategies, and innovative maintenance approaches that maximize productivity while minimizing operational costs in metal mining environments.

The Strategic Role of Tertiary Crushing

In mineral processing circuits, tertiary crushing bridges the gap between coarse reduction and grinding operations. This stage specifically targets particle size reduction to enhance mineral liberation - freeing valuable metals from host rock matrices. The efficiency of tertiary crushing directly influences downstream grinding energy consumption, with properly sized feed material reducing mill workload by 15-25%. Modern metal mines implement multi-stage reduction strategies where cone crushers handle the final size reduction before material enters grinding mills.

Feed material characteristics from secondary crushing stages present unique challenges. Ore hardness variations require crushers that adapt to changing conditions without compromising output consistency. The interlocked structure of partially liberated minerals demands precise compressive forces to achieve clean mineral separation. Through optimized tertiary crushing, operations can significantly improve concentrate grades while reducing overgrinding of valuable minerals.

Crushing Stage Classification Standards

Primary crushing reduces run-of-mine ore to 200-300mm fragments, while secondary processing achieves 50-100mm sizing. Tertiary crushing further reduces material to 5-25mm particles optimized for grinding circuit feed. This staged approach minimizes energy consumption across the entire comminution process.

Mineral Liberation Enhancement

Properly sized tertiary output creates clean fracture lines along mineral grain boundaries. This liberation efficiency reduces the grinding workload and improves flotation recovery rates by 3-8% compared to poorly crushed feed.

Feed Size Control Requirements

Consistent 50-100mm feed from secondary circuits ensures stable operation of multi-cylinder hydraulic cone crushers. Oversized material causes choking, while undersized particles reduce crushing efficiency through inadequate inter-particle compression.

Grinding Circuit Interface Specifications

Tertiary discharge must meet strict size distribution curves to optimize grinding media effectiveness. The ideal particle profile contains minimal fines while eliminating oversized fragments that reduce mill throughput capacity.

Technical Advantages of Hydraulic Systems

Multi-cylinder hydraulic cone crushers outperform traditional spring-type machines through advanced engineering solutions. Multiple hydraulic cylinders distributed around the crushing chamber provide balanced compressive force, enabling consistent particle size reduction across the entire crushing surface. This uniform pressure distribution extends wear part life by 30-40% compared to single-point loading systems.

The hydraulic overload protection mechanism instantly responds to tramp metal events, automatically releasing pressure before component damage occurs. This system then rapidly resets without manual intervention, minimizing downtime. Precision hydraulic controls enable real-time adjustment of discharge settings during operation, maintaining exact product specifications despite wear progression. These features collectively deliver superior throughput consistency in demanding mining applications where ore characteristics frequently fluctuate.

Hydraulic Overload Protection

Instant pressure release mechanisms activate within 0.5 seconds of uncrushable material detection, protecting critical components from impact damage. The system automatically resets once obstructions clear the crushing chamber.

Multi-Cylinder Force Distribution

Equally spaced hydraulic cylinders apply uniform pressure across the crushing mantle, eliminating localized stress points. This balanced loading produces more consistent particle shapes while reducing structural fatigue.

Automated Discharge Control

Closed-loop hydraulic systems continuously monitor and adjust the crusher's closed-side setting with ±1mm accuracy. This maintains product size consistency throughout wear component service life without production stoppages.

Compact Structural Design

Integrated hydraulic systems eliminate external accumulators and associated piping, reducing the crusher's footprint by 15-20% compared to spring-type equivalents. This space efficiency simplifies installation in confined mine processing plants.

Equipment Selection Methodology

Proper crusher selection requires comprehensive analysis of operational parameters and material characteristics. Processing capacity calculations must account for ore density fluctuations and hardness variations, typically adding 20% safety margin above projected peak production rates. The crusher's feed opening dimensions must accommodate maximum expected particle sizes from secondary circuits, preventing bridging and ensuring smooth material flow.

Crushing chamber configuration significantly influences product gradation and mineral liberation efficiency. Short-head chamber designs produce finer output ideal for precious metal recovery, while standard chambers generate coarser products suitable for base metal operations. Modern crushers incorporate hydraulic chamber clearing systems that rapidly discharge material during power interruptions, preventing costly material packing incidents. These selection criteria ensure optimal performance throughout the equipment lifecycle.

Capacity Matching Calculations

Throughput formulas incorporate material bulk density, crushability index, and moisture content to determine required processing capacity. Advanced selection software simulates various ore blends to identify optimal crusher specifications.

Feed Size Compatibility

Crusher openings must accommodate the 95th percentile particle size from upstream processes. Proper feed dimensioning prevents bridging and ensures optimal feed size distribution across the crushing chamber.

Chamber Type Selection

Standard chambers prioritize throughput for base metal operations, while short-head configurations maximize fines production for precious metal recovery. Specialized designs balance these objectives for complex polymetallic ores.

Wear Component Economics

Lifecycle cost analysis evaluates manganese steel grades, considering both initial cost and expected service life. Premium alloys often deliver 30-40% longer operational periods despite higher upfront investment.

Chamber Configuration Strategies

Crushing chamber geometry directly influences mineral liberation efficiency and product quality. Parallel zone length determines material retention time, with longer parallel sections increasing particle-to-particle crushing for improved mineral separation. Modern crushers feature hydraulically adjustable chamber profiles that adapt to changing ore characteristics without component replacement.

Specialized liner profiles minimize over-crushing of already liberated minerals, reducing slimes generation that complicates downstream processes. Advanced computer modeling optimizes throw and compression angle combinations for specific ore types, maximizing liberation while minimizing energy consumption. These innovations allow single machines to process diverse ore blends without compromising performance.

Parallel Zone Optimization

Extended parallel sections increase inter-particle crushing events, enhancing mineral liberation. Optimal lengths range from 250-400mm depending on ore characteristics and target product size.

Dynamic Profile Adjustment

Hydraulic chamber control systems modify crushing geometry in response to ore hardness changes. This maintains consistent product quality despite variations in feed material characteristics.

Material Flow Engineering

Computer-optimized liner profiles create efficient material trajectories through the crushing chamber. This reduces recirculation and minimizes power consumption per ton processed.

Wear Pattern Management

Asymmetric liner designs distribute wear more evenly across crushing surfaces. This extends service intervals by 20-30% while maintaining consistent product gradation throughout the wear cycle.

Operational Parameter Optimization

Precise control of crushing parameters maximizes efficiency and product quality. Hydraulic pressure settings determine compressive force intensity, with optimal ranges varying according to ore competency. Modern crushers incorporate variable frequency drives that enable precise eccentric speed adjustment, balancing throughput and particle shape requirements. Automated control systems continuously monitor power draw and adjust operating parameters to maintain peak efficiency despite feed variations.

Closed-loop discharge setting control utilizes laser measurement systems to maintain precise output sizing. These systems automatically compensate for liner wear, ensuring consistent product gradation throughout wear component service life. Integrated feed rate control synchronizes upstream equipment with crusher capacity, preventing both overfeeding that causes choking and underfeeding that reduces efficiency. This holistic approach to process optimization typically increases throughput by 15-20% while reducing energy consumption.

Dynamic Discharge Control

Laser measurement systems continuously monitor the actual discharge size, triggering automatic hydraulic adjustments when deviations exceed ±1mm. This maintains product consistency without operator intervention.

Intelligent Speed Regulation

Variable frequency drives optimize eccentric speed based on real-time power consumption and cavity level monitoring. This balances production rate with product shape requirements.

Automated Feed Management

Weightometer-controlled feeders maintain optimal cavity fill levels by modulating belt speed. This prevents overloading while ensuring continuous material coverage across the crushing surface.

Dust Control Synchronization

Water spray systems activate precisely during material transfer points, synchronized with crusher discharge cycles. This reduces water consumption by 40% while maintaining effective dust suppression.

System Integration Principles

Effective tertiary crushing requires seamless integration with upstream and downstream processes. Buffer storage capacity between crushing stages accommodates equipment maintenance and process fluctuations without disrupting overall production. Conveyor speed controls synchronize material flow with crusher capacity, preventing both starvation and overload conditions. Screening efficiency directly impacts crusher performance, with properly sized pre-screens removing fines that otherwise consume crushing capacity.

Modern plants implement centralized control systems that monitor the entire crushing circuit. These systems automatically adjust operating parameters across multiple equipment platforms to maintain optimal balance. Metal detection systems protect crushers from tramp steel damage, while magnetic separators remove ferrous contaminants from the product stream. This integrated approach maximizes overall system efficiency while minimizing operational disruptions.

Process Buffer Design

Surge bins between crushing stages provide 20-30 minutes of operational buffer capacity. This accommodates minor upstream disruptions without impacting tertiary crusher feed consistency.

Conveyor-Crusher Synchronization

Variable speed drives adjust conveyor rates based on crusher power consumption. This maintains optimal feed rates despite variations in material density and flow characteristics.

Screening Efficiency Optimization

Properly sized pre-screens remove 30-40% of fines before crushing, increasing effective throughput capacity. Post-crushing verification screens ensure final product quality compliance.

Centralized Control Implementation

Plant-wide monitoring systems collect over 200 operational parameters, using advanced algorithms to optimize the complete mineral processing circuit in real-time.

Maintenance and Cost Management

Predictive maintenance strategies maximize crusher availability while controlling operational expenses. Oil analysis programs detect early signs of component wear through metallic particle monitoring, allowing planned interventions before failures occur. Advanced liner wear monitoring systems utilize ultrasonic measurement technology to predict remaining service life with 90% accuracy, enabling just-in-time replacement scheduling.

Energy consumption represents 40-50% of crushing operational costs. Power monitoring systems identify optimization opportunities, with variable frequency drives typically reducing energy usage by 15-20%. Strategic spare parts inventory management employs usage-based algorithms to maintain optimal stock levels while minimizing capital investment. These approaches collectively reduce operating costs by 25-30% while extending equipment service life.

Hydraulic System Maintenance

Regular fluid analysis detects contamination before component damage occurs. High-pressure filter systems maintain fluid cleanliness below ISO 16/14/11 standards, extending pump and valve service life.

Wear Life Prediction Models

Machine learning algorithms analyze operational data to forecast liner wear patterns. These predictions enable planned maintenance during scheduled shutdowns, avoiding unplanned downtime.

Energy Monitoring Systems

Real-time power consumption tracking identifies inefficient operating conditions. Automated optimization routines adjust crusher parameters to maintain peak efficiency despite changing ore characteristics.

Inventory Optimization Techniques

Usage-based inventory systems classify components according to criticality and consumption patterns. This reduces carrying costs by 25-40% while maintaining 98% part availability for critical components.

Future Technological Developments

The next generation of cone crushers incorporates advanced technologies that further enhance efficiency and control. Electric hydraulic systems replace conventional pumps with servo-controlled units that reduce energy consumption by 25-30%. Digital twin technology creates virtual replicas of physical crushers, enabling operators to simulate parameter changes before implementation.

Artificial intelligence algorithms analyze operational data to continuously optimize crushing parameters. These systems automatically adjust settings in response to ore hardness variations, maintaining peak efficiency without operator intervention. Remote monitoring platforms enable expert support from anywhere in the world, reducing response times for technical issues. These innovations collectively advance crushing technology toward fully autonomous operation with minimal human supervision.

Electro-Hydraulic System Advancements

Servo-controlled hydraulic pumps deliver precise flow rates on demand, eliminating energy waste associated with constant-flow systems. Regenerative circuits capture energy during the non-compression cycle.

Artificial Intelligence Implementation

Machine learning algorithms process operational data to identify optimal parameter combinations. These systems continuously refine crushing strategies based on actual performance results.

Digital Twin Applications

Virtual crusher models simulate operational changes before implementation. This enables risk-free optimization of parameters for specific ore blends and production targets.

Remote Monitoring Platforms

Cloud-based monitoring systems provide global access to operational data. Expert support teams analyze performance metrics and recommend optimizations without physical site visits.