Choosing the Right Mobile Crusher: Your Essential Guide

Mobile crushers revolutionize material processing by bringing powerful crushing capabilities directly to worksites. These versatile machines handle diverse materials like granite, basalt, concrete debris, and mineral ores, reducing large chunks into precisely sized aggregates between 5-150mm. This guide explores critical selection factors including crusher types, performance metrics, terrain adaptability, operational costs, and sustainability features. Understanding these elements ensures optimal equipment matching for construction, mining, or recycling applications.

Understanding Crusher Types and Their Applications

Different crushing tasks demand specialized machinery configurations. Each crusher type applies unique mechanical forces - compression, impact, or attrition - to transform materials into required specifications. Selecting appropriate technology depends on material hardness, desired output size, and production volume targets.

Jaw Crushers: Powerhouses for Primary Crushing

Jaw crushers utilize compressive force between fixed and moving plates, excelling at initial size reduction of hard materials. Their robust construction handles granite and basalt efficiently, producing coarse aggregates ideal for road bases. The mobile jaw crusher variant maintains this capability while offering relocation flexibility between sites.

Cone Crushers: Precision in Secondary Processing

Operating through gyrating mantles within concave bowls, cone crushers deliver consistent medium-to-fine aggregates. They're optimal for processing river gravel or limestone into uniform 20-50mm particles. Hydraulic adjustment systems permit real-time output calibration without stopping production.

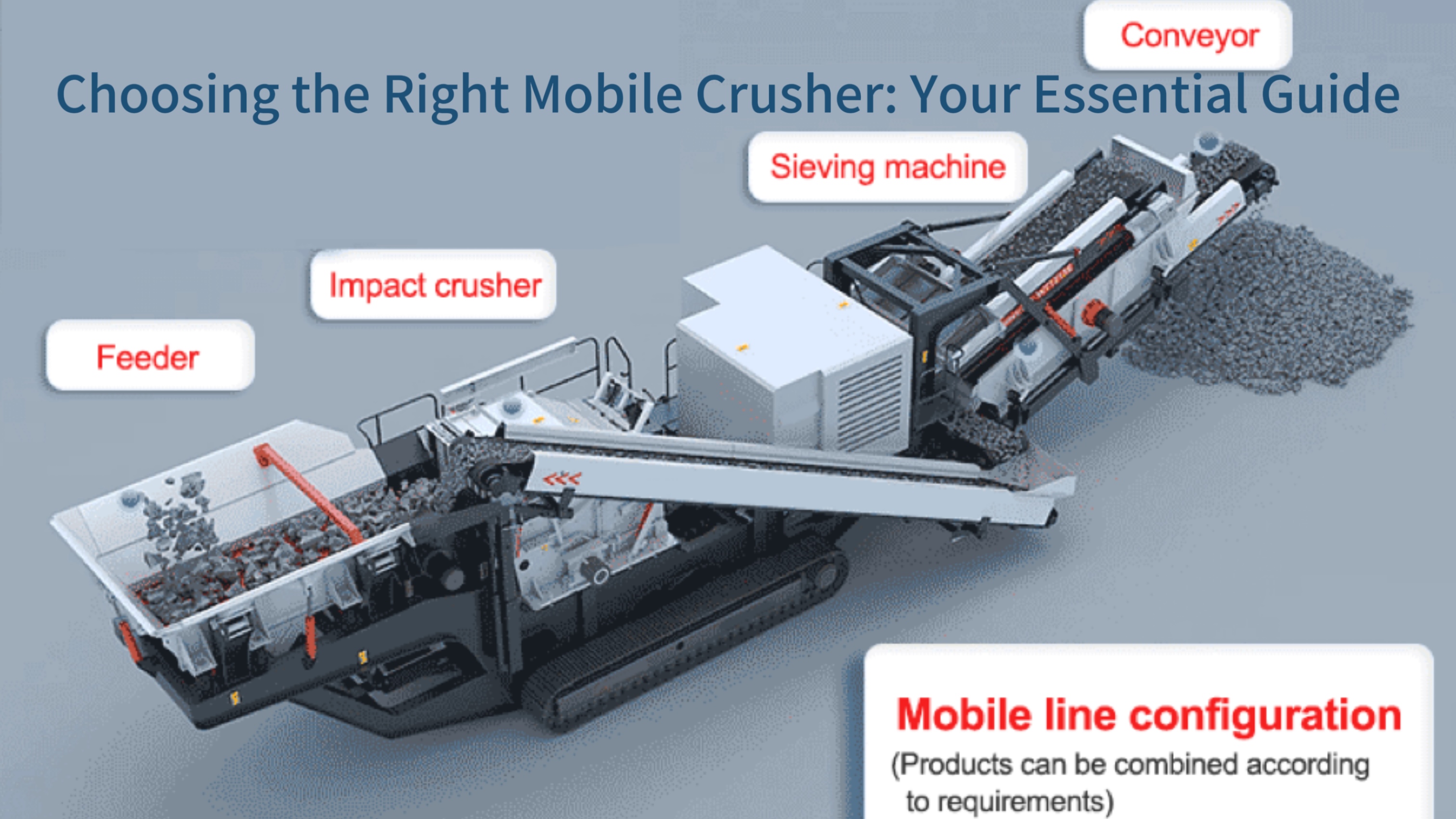

Impact Crushers: Versatility in Material Reduction

Rapidly rotating hammers strike materials against impact plates, making these units ideal for softer rocks and concrete recycling. This mechanism produces cubical aggregates essential for high-quality concrete mixes. Mobile configurations enable on-site processing of demolition waste.

VSI Crushers: Specialists in Aggregate Shaping

Vertical shaft impactors accelerate materials at high velocity against rock shelves, creating finely graded sands perfect for construction applications. Their unique rock-on-rock action yields optimally shaped particles with enhanced binding properties for concrete mixtures.

Tracked vs Wheeled Mobility Systems

Tracked crushers navigate challenging terrains like quarries with superior slope-climbing ability, while wheeled versions offer faster relocation on established roads. Your site accessibility and transfer frequency determine the optimal mobility solution.

Evaluating Performance Specifications

Beyond crusher type, operational specifications determine real-world productivity. Key metrics include throughput capacity, energy efficiency, and particle control mechanisms that collectively impact project economics and output quality.

Matching Capacity to Material Hardness

Throughput capacity (measured in tons per hour) varies significantly with material characteristics. Granite requires robust crushers with lower hourly output than equivalent limestone processing units. Manufacturers provide hardness-specific production charts for accurate selection.

Fuel Efficiency Considerations

Diesel consumption directly affects operating costs, with modern Tier-4 engines reducing fuel usage by 15-25% compared to legacy models. Hybrid systems further optimize consumption by supplementing diesel power with electric drive during appropriate crushing phases.

Crushing Ratio and Particle Control

The crushing ratio indicates size reduction capability, calculated as input versus output dimensions. Higher ratios enable single-stage processing of larger feed materials. Precise discharge size control is achieved through hydraulic adjustment systems or replaceable screen modules.

Protection Systems and Smart Controls

Hydraulic overload safeguards instantly release uncrushable objects, preventing catastrophic damage. Advanced IoT connectivity enables remote performance monitoring and operational adjustments from control rooms, enhancing safety and efficiency.

Environmental Adaptability Features

Mobile crushers encounter diverse operational challenges from Arctic temperatures to urban noise restrictions. Modern designs incorporate specialized features ensuring consistent performance across extreme conditions while meeting regulatory requirements.

Compact Site Maneuverability

Urban demolition projects demand crushers with minimized swing radii and retractable conveyors. Articulated steering systems and zero-tail-swing designs enable operation within confined spaces without compromising stability or safety.

Extreme Weather Preparedness

Arctic-grade crushers feature engine preheaters, insulated hydraulic lines, and cold-optimized lubricants enabling reliable cold-start operations at -30°C. Desert configurations incorporate enhanced air filtration and cooling systems protecting components from abrasive dust.

Emission and Noise Management

Urban-compliant models integrate advanced sound-dampening materials reducing operational noise below 85dB. Closed-circuit designs with integrated water-spray systems effectively suppress dust at transfer points, maintaining airborne particulate within regulatory limits.

Lifecycle Cost Analysis

Evaluating long-term operational expenses proves more crucial than initial purchase price. Strategic maintenance planning and component selection significantly impact total ownership costs over the equipment's service life.

Wear Component Longevity

Manganese steel jaw plates typically process 15,000-20,000 tons before replacement, while tungsten-tipped VSI rotors extend service intervals to 60,000+ tons. Material selection should align with processed substances' abrasiveness.

Maintenance Optimization Strategies

Centralized lubrication points and accessible service panels reduce downtime during routine maintenance. Remote diagnostics capabilities enable technicians to anticipate component failures, scheduling replacements during planned maintenance windows.

Ownership Model Comparison

Equipment leasing provides flexibility for short-term projects with maintenance included, while long-term operations benefit from purchasing with customized service agreements. Lifecycle cost calculators help determine the optimal financial approach.

Supplier Selection Criteria

Choosing the right equipment partner ensures ongoing technical support and operational success. Key evaluation factors include engineering expertise, support infrastructure, and industry-specific experience.

Technical Support Capabilities

Leading manufacturers provide material testing services to recommend optimal configurations. Customizable options include specialized wear liners for high-silica content rocks or reinforced rotors for reinforced concrete recycling.

Global Support Infrastructure

Reliable spare parts networks ensure critical components like hydraulic pumps or bearings are available locally within 24 hours. Suppliers with regional warehouses minimize operational disruptions during unplanned maintenance.

Environmental Compliance Assurance

Reputable manufacturers provide comprehensive documentation confirming compliance with international standards. These certifications validate adherence to emissions regulations and workplace safety requirements.

Practical Application Guidelines

Real-world implementation reveals crucial operational insights beyond technical specifications. These practical considerations prevent costly mismatches between equipment capabilities and project requirements.

Construction Waste Processing

Construction debris recycling demands impact crushers with electromagnetic separators and adjustable speed controls. Oversized crushers unnecessarily increase fuel consumption when processing predominantly wood and drywall debris.

Mining and Quarrying Operations

Mining applications require rugged track-mounted units capable of processing abrasive ores. Undersized feeders cause bottlenecks, while excessive capacity wastes fuel during lower-demand periods.

Sand Production Efficiency

VSI crushers achieve optimal particle shape when paired with prescreening units removing fines before crushing. Adjustable cascade flow controls distribute material evenly across rotors, maximizing liner utilization.

Emerging Technologies and Sustainability

The crushing industry is evolving toward greener, smarter solutions. Innovations focus on reducing environmental impact while enhancing operational efficiency through digital integration and alternative energy adoption.

Electrification Advancements

Battery-electric crushers eliminate jobsite emissions while reducing noise pollution. Solar-assisted charging systems extend operational periods in remote locations, supported by regenerative braking technology capturing energy during deceleration.

Intelligent Optimization Systems

AI algorithms continuously analyze material feed characteristics, automatically adjusting crusher settings for optimal particle shape and production rates. These systems reduce operator workload while maximizing output quality.

Circular Economy Integration

Equipment-sharing platforms optimize utilization rates by connecting idle machines with nearby projects. Manufacturers now offer crushing-as-a-service models where customers pay per ton processed, eliminating capital investment requirements.