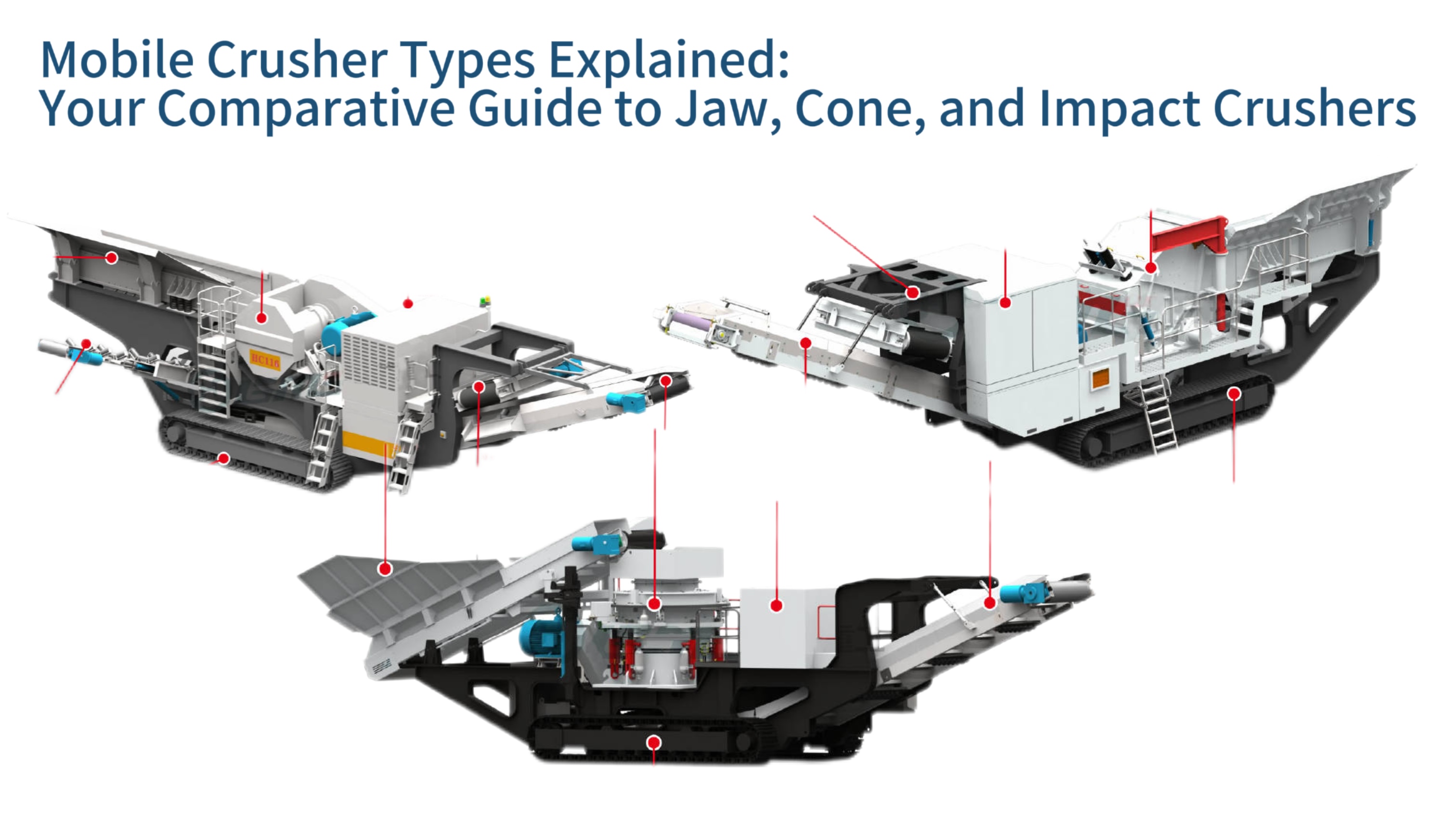

Mobile Crusher Types Explained: Your Comparative Guide to Jaw, Cone, and Impact Crushers

Selecting the right mobile crusher is crucial for efficient material processing in construction, mining, and recycling operations. This guide compares the three primary crusher types - jaw, cone, and impact crushers - examining their distinct working principles, material compatibility, performance metrics, and operational characteristics. By understanding how each machine handles different rock hardness levels, produces specific particle sizes, and manages operational costs, you'll gain the knowledge needed to match equipment to your project's unique requirements.

Fundamental Working Principles Compared

Each crusher type employs distinct mechanical forces to reduce material size, directly influencing their applications and efficiency. Understanding these core mechanisms helps predict how machines will perform with specific materials and desired outputs.

Jaw Crushers: Compression-Based Reduction

Jaw crushers feature two opposing plates where one moves in an elliptical motion against a stationary plate. This creates a powerful compressive force that fractures materials through direct pressure. The movable jaw plate generates a chewing-like action that efficiently breaks larger rocks into manageable chunks during primary crushing stages.

Cone Crushers: Precision Gyrating Motion

Operating through an eccentric rotating assembly, cone crushers compress materials between a gyrating mantle and stationary concave. This "squeeze and release" action creates a consistent crushing chamber that progressively reduces material size through multiple compression cycles, making it ideal for secondary crushing applications.

Impact Crushers: High-Velocity Fragmentation

Impact crushers accelerate materials against rigid surfaces using rapidly rotating rotors equipped with hammers or blow bars. This kinetic energy transfer causes materials to fracture along natural fault lines. The rotor assembly can be adjusted to control impact velocity, directly influencing particle shape and size distribution.

Energy Transfer Efficiency

Jaw crushers typically convert 60-70% of input energy into actual crushing force through direct mechanical advantage. Cone crushers achieve slightly higher efficiency (65-75%) due to continuous compression cycles, while impact crushers may experience more energy loss (50-65%) from material acceleration and rebound effects.

Material Compatibility and Size Requirements

Crusher performance varies significantly with material characteristics. Matching machine capabilities to geological properties ensures optimal productivity and prevents premature wear or damage to components.

Jaw Crushers for Hard Rock Applications

Designed for high compressive strength materials, jaw crushers excel with granite and basalt processing. Their robust construction withstands the intense pressures needed to fracture rocks with Mohs hardness above 6. The straight crushing chamber efficiently handles large feed sizes up to 1500mm.

Cone Crushers for Medium-Hard Materials

Ideal for limestone and iron ore processing, cone crushers operate effectively on materials with Mohs hardness between 3-6. Their interparticle crushing action produces more uniform cubical products than jaw crushers, with typical output sizes ranging from 20-80mm.

Impact Crushers for Soft and Recycled Materials

Excelling with softer materials like concrete and asphalt, impact crushers efficiently process recycled construction debris. They tolerate moderate clay content better than other crushers and produce well-graded aggregate for construction applications. Their construction waste recycling capabilities make them valuable in urban demolition projects.

Particle Size Control Capabilities

Jaw crushers typically produce coarse output (150-300mm) ideal for primary reduction. Cone crushers generate medium-sized particles (20-80mm) suitable for concrete production. Impact crushers offer the finest control, capable of producing precisely graded material down to 5mm when equipped with adjustable aprons.

Performance Metrics and Operational Efficiency

Quantifiable parameters provide objective comparison points between crusher types. These measurements directly impact project timelines and profitability through production rates and resource consumption.

Throughput Capacity Ranges

Jaw crushers typically handle 50-800 tons per hour (TPH), making them versatile for medium-scale operations. Cone crushers offer higher capacities of 80-1200 TPH for larger projects. Impact crushers fall between these ranges at 70-900 TPH, with capacity highly dependent on material characteristics.

Energy Consumption Profiles

Jaw crushers consume 0.5-1.2 kWh per ton processed, with diesel versions using 15-30 liters per hour. Cone crushers operate at 0.7-1.5 kWh/ton, while impact crushers require 0.8-2.0 kWh/ton due to their higher rotational energy demands.

Reduction Ratio Capabilities

The crushing ratio indicates size reduction efficiency. Jaw crushers achieve ratios of 3:1 to 5:1, meaning input sizes are reduced by 3-5 times. Cone crushers offer higher ratios of 4:1 to 8:1, while impact crushers can reach 10:1 to 20:1 reductions in certain configurations.

Automation and Control Systems

Modern crushers feature integrated IoT sensors that monitor performance metrics in real-time. Cone crushers typically lead in automation with self-adjusting settings that maintain consistent discharge size despite wear, while impact crushers offer simpler adjustment mechanisms.

Maintenance Requirements and Costs

Long-term operational expenses significantly impact total ownership costs. Understanding wear patterns and maintenance intervals helps predict and budget for ongoing equipment expenses.

Wear Component Lifespan Comparison

Jaw crusher cheek plates last 500-800 operating hours in abrasive conditions. Cone crusher mantles and concaves endure 800-1200 hours. Impact crusher blow bars wear fastest at 300-600 hours due to direct impact forces. Material selection can extend these intervals by 30-50%.

Hydraulic System Maintenance

Cone crushers feature complex hydraulic systems requiring quarterly fluid changes and filter replacements. Jaw crushers utilize simpler hydraulic systems for adjustment only, needing semi-annual maintenance. Impact crushers have minimal hydraulic components beyond basic adjustment functions.

Engine Maintenance Protocols

Diesel engines in mobile crushers require strict adherence to maintenance schedules. Air filter replacements every 250 hours prevent dust ingestion, while oil changes every 500 hours maintain lubrication efficiency. Turbocharger inspections every 1000 hours prevent catastrophic failures.

Real-World Application Scenarios

Practical implementation reveals how theoretical specifications translate to actual job site performance across different industries and environments.

Urban Demolition Projects

Impact crushers excel in concrete recycling applications due to their ability to liberate rebar from concrete and produce clean aggregate. Their closed-circuit configurations with magnetic separators efficiently process mixed demolition debris on-site.

Hard Rock Quarry Operations

Primary mobile jaw crushers followed by mobile cone crushers create efficient two-stage crushing circuits for granite and basalt. This combination maximizes reduction efficiency while controlling particle shape for asphalt production.

Limestone Processing Plants

Cone crushers are preferred for limestone processing due to their ability to produce consistent aggregate sizes with low fines generation. Their interparticle crushing action creates cubical products ideal for concrete mixing when processing medium-hard materials.

Arctic Construction Challenges

In sub-zero temperatures, hydraulic systems require specialized low-viscosity fluids. Engine block heaters become essential, and electric-driven crushers gain advantage by eliminating cold-start diesel challenges. Enclosed operator stations maintain productivity in harsh conditions.

Future Technological Developments

Crusher technology continues evolving toward greater efficiency, autonomy, and sustainability, reshaping material processing operations.

Electrification Advancements

Battery-electric crushers now offer 8-10 hours of continuous operation, with rapid-swap battery systems minimizing downtime. Solar-assisted charging extends operational range in remote locations, reducing diesel dependency by 40-60%.

Intelligent Automation Systems

AI algorithms now automatically adjust crusher settings based on material feed characteristics and wear conditions. These systems optimize energy consumption while maintaining consistent output quality without operator intervention.

Modular Component Design

Quick-change crushing chambers reduce conversion time between applications from days to hours. Standardized interfaces allow swapping jaw, cone, or impact modules on a single carrier platform, increasing operational flexibility.

Selection Methodology and Best Practices

A systematic approach to crusher selection prevents costly mismatches between equipment capabilities and project requirements.

Material Analysis First

Begin with comprehensive material testing, determining hardness, abrasiveness, and moisture content. High-silica materials demand different wear protection than limestone, directly influencing crusher type selection.

Throughput Requirements

Calculate required hourly production rates considering both peak demand and average operational efficiency. Undersized crushers create bottlenecks, while oversized units waste fuel during partial-load operation.

Lifecycle Cost Analysis

Evaluate total ownership costs including purchase price, expected maintenance expenses, fuel consumption, and component replacement costs over the equipment's expected service life.

Operational Environment Assessment

Consider site access limitations, relocation frequency, and environmental regulations. Track-mounted units outperform wheeled versions on rough terrain, while electric models reduce noise in urban settings.