Gyratory Crusher

Conical Compression Crushing: Operates via a conical head gyrating within a concave bowl, generating progressive compression as material moves downward. Combines elements of jaw and cone crushers for ultra-high-capacity primary crushing.

Maintenance of Gyratory Crusher

Regular maintenance of a gyratory crusher is essential to ensure optimal performance, reduce downtime, and extend its operational lifespan. Proper inspections, timely replacements, and adherence to manufacturer guidelines help maintain efficiency and reliability.

Routine Inspections and Monitoring

Frequent visual inspections help detect early signs of wear, cracks, or misalignment in key components. Monitoring for unusual vibrations, noise, and temperature fluctuations can prevent unexpected failures.

Lubrication System Maintenance

Ensuring proper lubrication is crucial for reducing friction and preventing overheating. The lubrication system should be checked regularly, and oil levels must be maintained to avoid damage to bearings and other moving parts.

Checking and Replacing Wear Parts

Wear parts such as mantles, concaves, and liners need periodic inspection and replacement. Worn-out components can reduce crushing efficiency and increase stress on the machine, leading to costly repairs.

Monitoring the Mantle and Concave Alignment

Misalignment of the mantle and concave can affect the crushing process. Regularly checking and adjusting their positioning ensures uniform crushing action and consistent product size.

Ensuring Proper Feed Distribution

Uneven feed distribution can cause excessive wear and reduce efficiency. Operators should ensure that materials are evenly distributed across the crushing chamber to minimize localized wear and maximize throughput.

Checking the Hydraulic and Adjustment System

The hydraulic system plays a crucial role in adjusting the crusher settings and maintaining pressure control. Regularly inspecting hydraulic components helps prevent leaks and system failures.

Inspecting the Main Shaft and Bearings

The main shaft and bearings must be in good condition for smooth operation. Checking for signs of wear, overheating, or misalignment ensures the machine operates efficiently without unexpected breakdowns.

Cleaning and Dust Control

Dust buildup around critical components can lead to overheating and premature wear. Regular cleaning and using dust suppression systems help maintain a safe and efficient working environment.

Ensuring Proper Torque and Fastener Tightening

Bolts and fasteners should be checked and tightened according to manufacturer specifications. Loose fasteners can lead to structural issues and component misalignment.

Following a Preventive Maintenance Schedule

Adhering to a structured preventive maintenance schedule minimizes downtime and improves crusher longevity. Regular maintenance logs and performance monitoring ensure optimal operation and timely part replacements.

Applications of Gyratory Crusher

Gyratory crushers are widely used across various industries due to their ability to handle large feed sizes, high capacities, and efficient crushing mechanisms. Their applications range from mining and aggregate production to industrial material processing, making them essential in heavy-duty crushing operations.

Primary Crushing in Mining

Gyratory crushers are commonly used as primary crushers in mining operations. They efficiently process large and hard ores, reducing them to a manageable size for further processing. Their high capacity and robust design make them ideal for handling tough materials in open-pit and underground mining.

Aggregate Production

In the construction industry, gyratory crushers play a vital role in producing high-quality aggregates. They are used to crush large rocks into uniform sizes for road construction, concrete production, and asphalt mixing, ensuring durability and structural integrity.

Processing of Metallurgical Ores

Gyratory crushers are widely used in metallurgical processing plants to crush various metal ores such as iron ore, copper ore, and nickel ore. Their ability to handle abrasive materials efficiently makes them suitable for refining raw minerals before further processing.

Cement Industry Applications

The cement industry utilizes gyratory crushers for crushing raw materials like limestone, clay, and shale. These materials are essential for cement production, and gyratory crushers ensure consistent particle sizes to improve the efficiency of the grinding and mixing processes.

Coal and Energy Sector

Gyratory crushers are also used in coal processing plants to break down large coal lumps into smaller, more manageable sizes. This application enhances the efficiency of coal-fired power plants and other energy production processes.

Construction and Infrastructure Development

Large-scale infrastructure projects, such as bridges, highways, and tunnels, require crushed materials of specific sizes. Gyratory crushers provide high-capacity crushing solutions, ensuring a continuous supply of aggregates for large construction projects.

Recycling and Waste Management

In recycling applications, gyratory crushers are used to process concrete, asphalt, and demolition debris. They help reduce waste materials into reusable aggregates, promoting sustainable construction practices and reducing landfill usage.

Industrial Mineral Processing

Gyratory crushers are essential in processing industrial minerals such as gypsum, phosphate, and salt. Their efficient crushing action ensures uniform particle sizes, improving the quality and usability of these materials in various industrial applications.

How to Choose the Right Gyratory Crusher?

Choosing the right gyratory crusher is essential for optimizing crushing efficiency, minimizing operational costs, and ensuring long-term productivity. Several factors, including feed size, capacity requirements, material characteristics, and operational conditions, must be considered when selecting the ideal gyratory crusher for a specific application.

Understanding the Crushing Application

The first step in selecting a gyratory crusher is understanding the specific application requirements. Gyratory crushers are commonly used in primary crushing applications for processing large and hard materials. Knowing whether the crusher will be used for mining, aggregate production, or industrial applications helps determine the most suitable model.

Considering Feed Size and Material Type

The size and hardness of the material to be processed are crucial factors. Gyratory crushers are designed to handle large feed sizes, but different models accommodate varying material characteristics. Harder materials require crushers with higher power and stronger wear components, while softer materials may allow for more efficient energy usage.

Evaluating Capacity Requirements

Production capacity is a key factor when choosing a gyratory crusher. The crusher must be able to process the required amount of material efficiently without bottlenecks. Selecting a model that meets or exceeds production goals ensures consistent operation and prevents unnecessary downtime.

Assessing Energy Efficiency

Gyratory crushers consume significant energy, making efficiency a crucial consideration. Advanced models incorporate energy-saving features that reduce power consumption while maintaining high throughput. Choosing an energy-efficient crusher helps lower operational costs and enhances sustainability.

Examining Maintenance and Wear Parts

Regular maintenance is necessary to keep a gyratory crusher running efficiently. Crushers with easily replaceable wear parts and accessible maintenance points reduce downtime and maintenance costs. Features such as automated lubrication systems and wear monitoring sensors improve reliability and extend component lifespan.

Considering Automation and Control Systems

Modern gyratory crushers often come with advanced automation and control systems that optimize performance and improve safety. Features such as real-time monitoring, automatic adjustments, and overload protection enhance operational efficiency and reduce manual intervention.

Ensuring Structural Durability

A gyratory crusher must be built to withstand extreme loads and continuous operation. Heavy-duty frames, reinforced components, and high-quality materials ensure long-term durability and resistance to wear, especially in demanding mining and aggregate applications.

Comparing Different Models and Brands

Different manufacturers offer various models with unique features. Comparing specifications, performance ratings, and customer reviews helps in selecting the most suitable gyratory crusher. Consulting with experts or suppliers can also provide insights into the best options for specific needs.

Balancing Cost and Performance

While the initial investment is important, long-term operational costs must also be considered. Choosing a gyratory crusher with a balance between affordability, efficiency, and durability ensures maximum return on investment and sustained productivity.

Stone Crusher Types

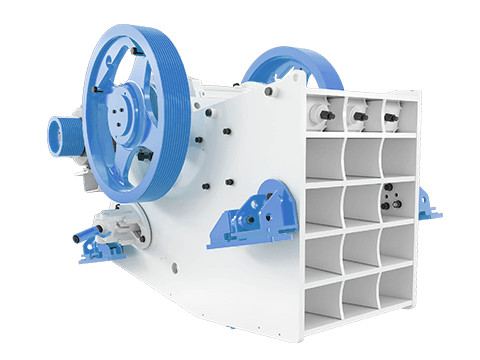

Jaw Crusher

Compressive Crushing: Utilizes compressive force generated by a reciprocating motion between a fixed jaw plate and a movable jaw plate. The material is crushed by progressive compression as it moves downward through the crushing chamber.

Learn more >>

Cone Crusher

Employs interparticle crushing (also called layer compression), where rocks are crushed between a rotating mantle and a concave liner. The eccentric gyratory motion of the mantle creates a compressive force field, inducing fractures along grain boundaries.

Learn more >>

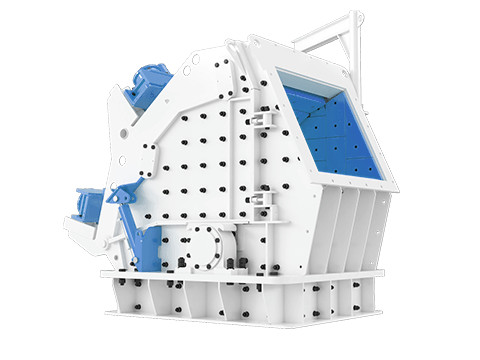

Impact Crusher

Dynamic Impact Crushing: Relies on kinetic energy transfer via high-speed rotors equipped with blow bars or hammers. Material is shattered by direct impact against rotating components or stationary anvils, with secondary fragmentation occurring through particle-on-particle collisions.

Learn more >>

Roll Crusher

Shear-Compression Crushing: Applies shear-compression forces between counter-rotating rolls with textured or smooth surfaces. Material is drawn into the gap (nip angle) and fragmented via tensile failure or surface abrasion.

Learn more >>

Hammer Crusher

Dynamic Impact with Grinding: Combines high-velocity hammer strikes (rotating hammers on a horizontal shaft) with material grinding against breaker plates or screens. Fragmentation occurs through impact, attrition, and shear.

Learn more >>

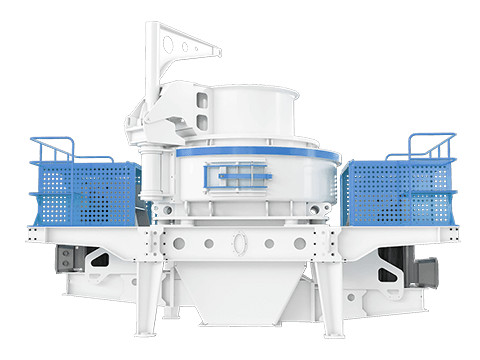

VSI Crusher

Centrifugal Acceleration Crushing: Accelerates material through a high-speed rotor (up to 70 m/s) and projects it against a stationary anvil or rock-lined chamber, exploiting centrifugal force and interparticle collision for fragmentation.

Learn more >>

Gyratory Crusher

Conical Compression Crushing: Operates via a conical head gyrating within a concave bowl, generating progressive compression as material moves downward. Combines elements of jaw and cone crushers for ultra-high-capacity primary crushing.

Learn more >>

Fine Crusher

Fine Crusher is engineered for reliable and stable operation, making it an ideal choice for fine crushing applications across various industries.

Learn more >>

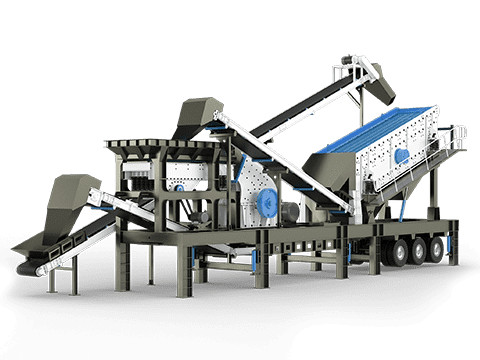

Mobile Crusher

The Mobile Crusher is designed to operate as a primary or secondary unit, making it a versatile choice for various applications.

Learn more >>