Roll Crusher

Shear-Compression Crushing: Applies shear-compression forces between counter-rotating rolls with textured or smooth surfaces. Material is drawn into the gap (nip angle) and fragmented via tensile failure or surface abrasion.

Maintenance of Roll Crusher

Regular maintenance of roll crushers is essential to ensure their longevity, efficiency, and safe operation. Proper upkeep helps prevent unexpected failures, reduces downtime, and maintains consistent crushing performance.

Routine Inspection and Monitoring

Frequent inspections help identify wear and tear, misalignment, and potential damage. Monitoring vibrations, unusual noises, and temperature variations can help detect issues before they escalate.

Lubrication of Bearings and Moving Parts

Proper lubrication minimizes friction and prevents overheating. Regularly checking and replenishing lubricants ensures smooth operation and extends the life of critical components.

Checking and Adjusting the Roll Gap

The roll gap determines the final product size and must be regularly checked and adjusted. Misalignment or excessive wear can affect particle size distribution and overall efficiency.

Inspecting and Replacing Wear Parts

Roll surfaces, teeth, and liners experience gradual wear over time. Replacing these components when necessary helps maintain optimal crushing performance and prevents excessive stress on the machine.

Ensuring Proper Belt Tension and Alignment

The drive belt plays a crucial role in roll crusher operation. Regularly checking and adjusting belt tension and alignment prevents slippage and ensures efficient power transmission.

Monitoring Overload Protection Systems

Roll crushers are equipped with overload protection mechanisms to prevent damage from uncrushable materials. Regularly testing these systems ensures they function properly during unexpected load conditions.

Cleaning and Removing Material Build-up

Accumulated material between the rolls or inside the crusher housing can cause blockages and reduce efficiency. Regular cleaning prevents material buildup and ensures continuous operation.

Checking Fasteners and Structural Integrity

Loose bolts and fasteners can lead to misalignment and structural issues. Periodically tightening and inspecting all fasteners ensures machine stability and operational safety.

Examining Hydraulic and Adjustment Systems

For roll crushers with hydraulic adjustment features, maintaining hydraulic pressure and checking for leaks is crucial. Proper function of adjustment mechanisms ensures consistent roll settings.

Following a Preventive Maintenance Schedule

Adhering to a structured maintenance schedule reduces the risk of unexpected breakdowns. Documenting maintenance activities helps track component lifespan and plan timely replacements.

Applications of Roll Crusher

Roll crushers are widely used in various industries for material reduction and size control. Their ability to handle different types of materials efficiently makes them essential in mining, construction, and industrial processing applications.

Primary and Secondary Crushing in Mining

Roll crushers are commonly used in mining operations for primary and secondary crushing. They effectively reduce large ore chunks into smaller sizes, making them easier to process in subsequent milling or refining stages.

Coal Processing in Power Plants

In coal-fired power plants, roll crushers are used to crush coal into uniform sizes before combustion. This ensures efficient burning and minimizes unburnt carbon residue in the ash.

Aggregate Production for Construction

Roll crushers play a crucial role in the production of aggregates for road construction, concrete manufacturing, and asphalt production. They produce well-graded materials suitable for infrastructure projects.

Cement Industry Applications

In cement production, roll crushers help process raw materials such as limestone and clay. Their ability to create consistent particle sizes improves the efficiency of grinding and blending processes.

Crushing of Industrial Minerals

Roll crushers are used in processing industrial minerals such as gypsum, salt, and phosphate. Their gentle crushing action minimizes fines generation, preserving the material’s usability.

Recycling and Waste Management

Recycling plants use roll crushers to process construction and demolition waste, breaking down concrete, bricks, and asphalt into reusable materials for sustainable construction.

Metallurgical and Chemical Processing

In metallurgical and chemical industries, roll crushers are employed to process raw materials, reducing them to specific sizes required for further chemical reactions or metal extraction.

Glass and Ceramic Industry

Roll crushers are used to break glass and ceramic materials into fine particles for recycling or manufacturing processes, ensuring minimal waste generation.

How to Choose the Right Roll Crusher?

Selecting the right roll crusher is crucial for optimizing material processing efficiency, reducing operational costs, and achieving the desired final product size. Factors such as material type, feed size, capacity, and maintenance requirements must be carefully considered when choosing a roll crusher for a specific application.

Understanding the Material Characteristics

The hardness, abrasiveness, and moisture content of the material being processed play a significant role in selecting a roll crusher. Softer materials may require smooth roll crushers, while harder or more abrasive materials may need crushers with teeth or impact-resistant components.

Determining the Required Feed Size and Output Size

Different roll crushers are designed to handle varying feed sizes and produce specific output sizes. The gap setting between the rolls determines the final product size, so it is essential to choose a crusher that can achieve the desired reduction ratio.

Evaluating Capacity and Throughput Requirements

The crusher must be capable of handling the expected material volume efficiently. Higher-capacity roll crushers are suitable for large-scale operations, while smaller units may be sufficient for lower production demands.

Considering the Type of Roll Crusher

There are different types of roll crushers, including single roll, double roll, triple roll, and quad roll crushers. Each type serves specific applications, with double roll crushers being the most common for fine and medium crushing, while single roll crushers are ideal for primary crushing.

Assessing Power Consumption and Efficiency

Energy efficiency is an important consideration when selecting a roll crusher. Some models come with advanced designs that minimize power consumption while maintaining high crushing efficiency, reducing overall operational costs.

Examining Wear Resistance and Durability

The roll surface material and construction quality determine the crusher’s longevity. Rolls made of high-strength alloys or carbide-reinforced surfaces offer better resistance to wear and abrasion, leading to lower maintenance requirements.

Analyzing Maintenance and Ease of Operation

Regular maintenance is necessary to ensure consistent performance. Choosing a roll crusher with easily replaceable wear parts, simple lubrication systems, and accessible components can reduce downtime and maintenance costs.

Checking Safety Features

Modern roll crushers come with built-in safety mechanisms such as overload protection, tramp iron relief, and automatic adjustments. These features help prevent damage to the machine and enhance operator safety.

Comparing Different Brands and Models

Manufacturers offer various roll crusher models with unique features. Comparing specifications, customer reviews, and expert recommendations helps in selecting the most reliable and cost-effective crusher for a given application.

Balancing Cost and Performance

While the initial purchase price is important, long-term operational costs, including maintenance, energy consumption, and wear part replacement, should also be considered. Choosing a well-balanced roll crusher ensures high efficiency and cost-effectiveness.

Stone Crusher Types

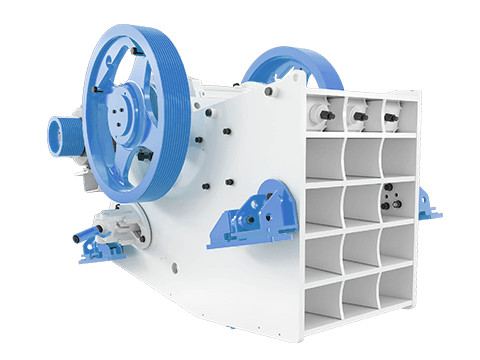

Jaw Crusher

Compressive Crushing: Utilizes compressive force generated by a reciprocating motion between a fixed jaw plate and a movable jaw plate. The material is crushed by progressive compression as it moves downward through the crushing chamber.

Learn more >>

Cone Crusher

Employs interparticle crushing (also called layer compression), where rocks are crushed between a rotating mantle and a concave liner. The eccentric gyratory motion of the mantle creates a compressive force field, inducing fractures along grain boundaries.

Learn more >>

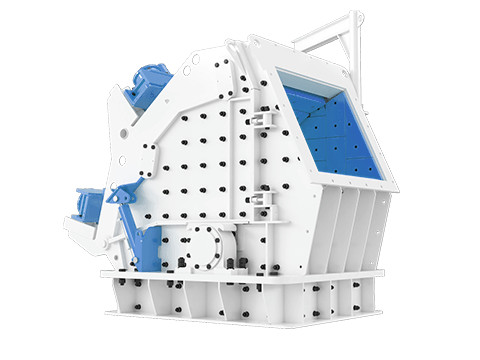

Impact Crusher

Dynamic Impact Crushing: Relies on kinetic energy transfer via high-speed rotors equipped with blow bars or hammers. Material is shattered by direct impact against rotating components or stationary anvils, with secondary fragmentation occurring through particle-on-particle collisions.

Learn more >>

Roll Crusher

Shear-Compression Crushing: Applies shear-compression forces between counter-rotating rolls with textured or smooth surfaces. Material is drawn into the gap (nip angle) and fragmented via tensile failure or surface abrasion.

Learn more >>

Hammer Crusher

Dynamic Impact with Grinding: Combines high-velocity hammer strikes (rotating hammers on a horizontal shaft) with material grinding against breaker plates or screens. Fragmentation occurs through impact, attrition, and shear.

Learn more >>

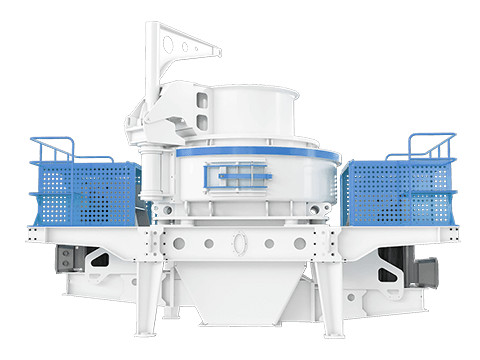

VSI Crusher

Centrifugal Acceleration Crushing: Accelerates material through a high-speed rotor (up to 70 m/s) and projects it against a stationary anvil or rock-lined chamber, exploiting centrifugal force and interparticle collision for fragmentation.

Learn more >>

Gyratory Crusher

Conical Compression Crushing: Operates via a conical head gyrating within a concave bowl, generating progressive compression as material moves downward. Combines elements of jaw and cone crushers for ultra-high-capacity primary crushing.

Learn more >>

Fine Crusher

Fine Crusher is engineered for reliable and stable operation, making it an ideal choice for fine crushing applications across various industries.

Learn more >>

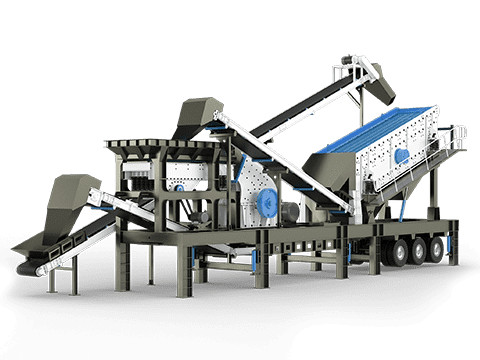

Mobile Crusher

The Mobile Crusher is designed to operate as a primary or secondary unit, making it a versatile choice for various applications.

Learn more >>